This section summarises surface products in buildings fulfilling European reaction to fire classes as described in Fire safety regulations in Europe.

To search all text on this page

On Windows – Press Ctl+F

On Mac – Command+F

This site is suitable for a wide range of users, with technical information

levels 1 and 2 available on closed toggles

Technical level 1 Technical level 2

Wood products as walls and ceilings

- Fire retardant treated (FRT) wood products

-

- Durability classes for fire performance

- European system with durability of reaction to fire performance (DRF) classes

Wood floorings

- Classes of reaction to fire performance for non-coated wood floorings

Reaction to fire

Reaction to fire means the response from materials to an initial fire attack, and includes properties like time to ignition, flame spread, heat release rate and smoke production. These properties are relevant in the early fire development, which is the stage when combustible construction products may contribute to the fire.

This fire performance characteristic of surfaces applies to all applications, internal and external. This section covers performance assessment for interiors. External applications in facades are covered here: Reaction to fire performance – external surfaces.

For building products used on the inside of buildings, a European system with reaction to fire classes A to F is defined for products except floorings, where classes A1 and A2 are for non-combustible products, which cannot be reached by wood products.

For floorings, a similar system is defined with classes Afl to Ffl, where “fl” means floorings. The fire performance is expressed as FIGRA, Fire Growth Rate, which is the main parameter used for the Euroclass system EN 13501-1 and measured by the SBI test EN 13823, see Fire safety regulations in Europe.

An overview of building products fulfilling different reaction to fire performance classes is presented in Tables 1 and 2 below.

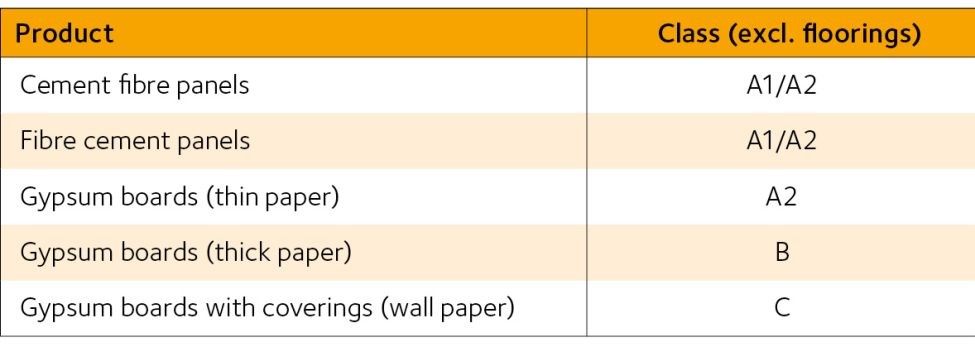

The most common non-combustible wall and ceiling linings are gypsum plasterboard and cement-based panels. The reaction to fire performance of some common non-combustible products for walls and ceilings is given in Table 1.

Table 1. Classes of reaction to fire performance of gypsum and other non-combustible products for walls and ceilings (Technical level 1)

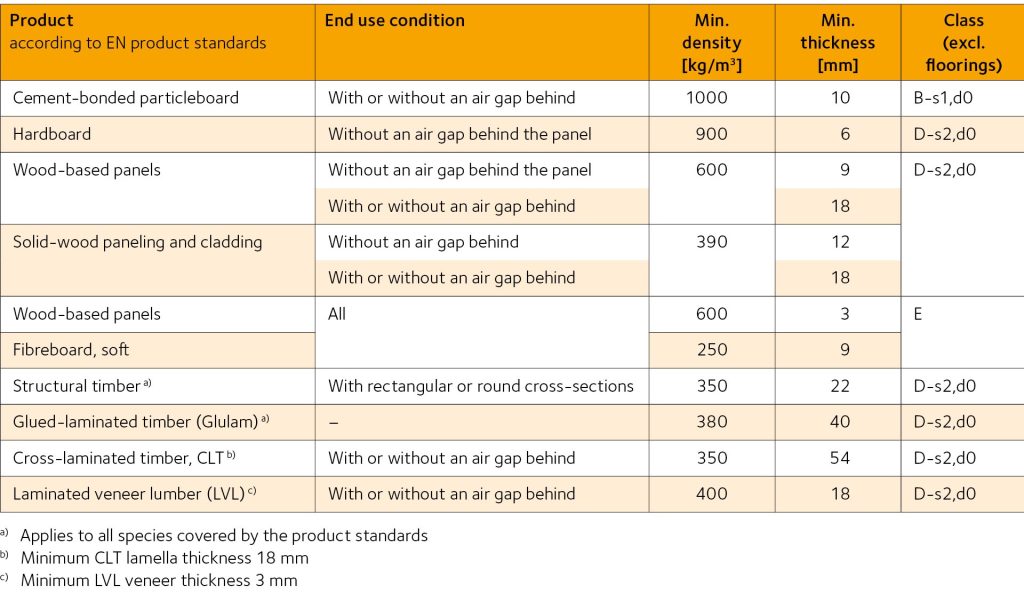

The reaction to fire performance of wood products for walls and ceilings is closely linked to the product density and thickness. Euroclasses have been determined for a range of wood products and published in the Official Journal. Whilst some configurations have been tested and are certified for use without further testing, it is vital to recognize that the test condition needs to be fully understood and identical to the proposed end-use application of the specific product. The jointing and mounting of materials, as well as the type, density and thickness of the product are vitally important in determining performance. Minor changes in materials and proposed set-up in use can lead to different performance and this would require additional testing to confirm suitability. This has been clarified in the European Commission Classified Without Further Testing (CWFT) standards, as follows:

- wood panelling and cladding, and wood flooring

- wood flooring

- wood-based panels

- structural timber (and gypsum plasterboard products)

- glulam

For UK users additional information can be found here.

Table 2. Classes of reaction to fire performance for wood products except floorings (Technical level 1)

It is relatively easy to obtain an improved fire performance for wood products. Most existing fire retardants are effective in reducing different reaction-to-fire parameters of wood. Flame retardant chemicals work by reducing the ignitability of a substrate, slowing down the spread of flame across a surface and, as a result, reducing the heat released. These effects combined can improve the reaction-to-fire classification of that substrate significantly. Untreated wood-based materials typically have Euroclass ratings of D or E. Flame retardant treatment can improve that to Euroclass B or C, as required by the particular specification and end use. Further information on how flame retardants work and the crucial difference between Reaction to Fire & Fire Resistance classifications can be found in WPA Guidance Note FR1. Further information on reaction to fire testing and performance classification can be found in WPA Guidance Note FR2. All WPA resources are available for free download from https://www.thewpa.org.uk/resources-for-flame-retardant-wood

High retention levels have to be used compared to ordinary preservation treatments used to protect wood against biological decay. It is important to recognise that fire retardants cannot make wood non-combustible.

For details of flame-retardant chemical products independently assessed and approved in the UK by the Wood Protection Association (WPA), and for information on processes and treated wood products visit https://www.thewpa.org.uk/flame-retardants

It should not be assumed that, because the reaction-to-fire rating of a wood-based substrate is uprated by flame retardant treatment, there is a reduced requirement for good design and workmanship. The flame-retardant pre-treatments recommended for the various commodities or end use situations are complementary to good design, workmanship and site practice – not a substitute for them.

Furthermore, the excellent fire performance of virgin FRT wood products may degrade over time, especially in outdoor applications. Thus, when exposed to high humidity, the FR chemicals may migrate in the wood towards the surface and may ultimately be leached out. Even at moderate outdoor humidity and indoors, the fire performance may deteriorate because the FR chemicals migrate away from the surface towards lower concentration regions deeper inside the material thus increasing the flammability of the product, see below.

A suitable specification must take into consideration the end use Service Environment for flame retardant treated products. This will have a direct bearing on the durability of the reaction-to-fire performance and hence classification. Some treatments are suitable only for internal applications (Class INT1) whilst others may be used on wood-based products to be used outdoors (e.g. cladding), either coated (Class INT2) or uncoated (Class EXT). Further guidance on how to specify the service environment of FR treated wood can be found in WPA Guidance Note FR3.

It is vital that any flame-retardant treatment required in a building provides long-term, predictable protection backed by independent verification. A Specification Checklist has been produced by the WPA as a useful guide to ensuring all the essential factors are included in such a specification. The documentary evidence required to verify that the specification has been met is also explained. That Checklist can be found in WPA Guidance Note FR6.

Further explanation of how to read and interpret the performance results given in a Reaction to Fire Test Classification report is given in WPA Guidance Note FR7.

The Wood Protection Association operates independent quality and approval schemes to underpin confidence in both the efficacy of a flame-retardant formulation and the subsequent application of that formulation to the wood substrate. Further details of the WPA Benchmark FR schemes can be found in WPA Guidance Note FR10 and a list of approved products and accredited treaters here: the wpa.org.uk

There are essentially three commercially available technology groups:

- Vacuum Pressure Treatment: Vacuum pressure impregnation process applied in factory based, large scale autoclaves with full factory process control in place. Suitable for solid timber and plywood post manufacture. INT2 & EXT class treatment options are available in the UK, both capable of upgrading material to either a Euroclass B or C classification.

- Manufactured wood-based panels: Wood-based panels products such as MDF, particleboard, flaxboard, OSB and plywood which incorporate FR chemicals as an integral part of manufacture where an enhanced reaction to fire rating is required. INT1 & INT2 options available, in either Class B or C (depending on product).

- Surface-applied products (Intumescent Coatings): Intumescent technology is well established with a long track record. Such coatings react to fire by expanding and forming a barrier on the substrate surface. This slows down ignition and spread of flame. Contact the manufacturer for end use performance details. Factory application under strict process control is recommended by the WPA.

CAUTION: SITE APPLIED COATINGS AND LOW VISCOSITY LIQUIDS

Formulations for surface application depend entirely on correct application rates and/or film thicknesses being achieved. When low viscosity coatings are applied by brush or spray on site, it is rarely possible to guarantee sufficient control of application quality to provide confidence in effective performance. For this reason, WPA will only consider applications for approval of such systems when applied under factory-controlled conditions.

Characteristics of treated materials

The properties of a flame retardant treated wood-based product will depend to a degree on the system used to treat the material and the specification to which it has been treated. It is important to obtain information from the supplier on the safe and effective use of the treated material. In particular, specifiers and users should ask for confirmation of:

-

- The standard of treatment: Euroclass & Service Environment

- Wood species/substrate details

- How to fabricate the product after treatment

- Any post-treatment drying requirements

- Any effect of flame-retardant treatment on mechanical and physical properties

- Any effect of flame-retardant treatment on compatibility with fittings etc

- Service life guidance

- Any in-service maintenance requirements

- Any specific handling precautions

Durability classes for fire performance

Two considerations of durability of FRT wood products can be identified. One is the risk of high moisture content and migration of the fire retardant chemicals within the wood product and salt crystallisation on the product surface. These hygroscopic properties of the treated wood-based product can be evaluated by exposure to high relative humidity.

The other is the risk of decreased fire performance due to loss of the fire retardant chemicals by leaching or other mechanisms. This case is mainly for exterior applications, e.g. as façade claddings. Maintained fire performance over time has to be verified. This system is recognised and implemented by the Wood Protection Association in the UK.

European system with durability of reaction to fire performance (DRF) classes (Technical level 1)

A European system with Durability of Reaction to Fire performance (DRF) classes EN 16755 has been developed in order to guide the potential users to find suitable FRT wood products:

- DRF class INT1 (interior dry conditions) with no durability requirements

- DRF class INT2 (interior humid conditions) with requirements on limited moisture content

The system consists of a classification system for the properties over time of FRT wood and suitable test procedures. It provides a useful supplement to requirements for fire performance in national building codes and provides guidance to potential users for finding suitable and reliable FRT wood products.

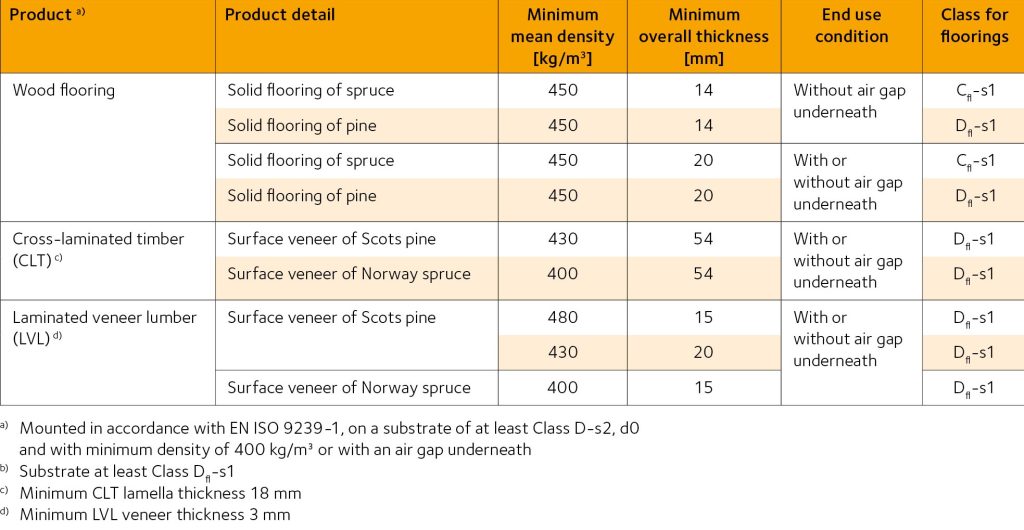

The reaction to fire performance of floorings is expressed in a similar system, with classes Afl to Ffl, where “fl” means floorings. Data for non-coated wood floorings are presented in Table 3, as published in the Official Journal.

Table 3. Classes of reaction to fire performance for non-coated wood floorings (Technical level 1)

Data for coated wood floorings have also been published in the Official Journal.