To search all text on this page

On Windows – Press Ctl+F

On Mac – Command+F

This site is suitable for a wide range of users, with technical information

levels 1 and 2 available on closed toggles

Technical level 1 Technical level 2

Prescriptive vs performance-based design

- Prescriptive design (ENs)

- Performance-based design

Fire safety strategy

- Qualitative design review process

Supporting guidance

- Excerpt from BS 7974:2019

Scope of performance-based design for structural elements

- Compartment fire dynamics

- Structural response

- External fire spread

Encapsulation of timber elements

- European harmonised standards

Calculation methods and approaches

- Prescriptive

- Performance-based

Routes to fire safety: Options

Prescriptive vs performance-based design

The fire performance of timber structures is a complex subject with many interacting requirements and considerations, spanning the entire timber construction ecosystem from supply chain to designer, regulator to client, insurer to user.

Many of the considerations are essentially independent of the construction material (timber or other) but are governed by the use of the building and the nature of its occupants as well as the height of the structure. The central aim is to ensure the safety of occupants and the fire rescue teams. Other requirements such as property/loss prevention can also be key, although these tend to be additional to national (building) regulations.

The designer has two principal design approaches available to meet the requirements:

- Prescriptive

- Performance-based (PB)

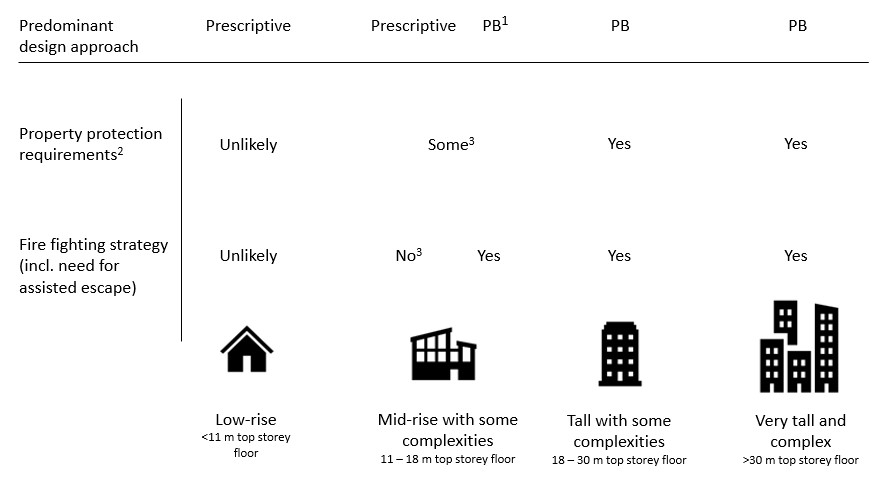

The choice of method(s) is often linked to the complexity of the building, as a function of its height and use (type of occupancy). Low-rise buildings, in which occupants are assumed to escape without assistance, tend to be designed using prescriptive approaches, whilst very tall, complex buildings tend to be designed using performance-based approaches.

In the UK both are used and available to designers. A design may incorporate a combination of both. Figure 1 below outlines the most commonly observed approaches and influencing factors for when each might be used. Depending on the fire safety strategy and complexity of the project other decision factors come into play. See also https://www.gov.uk/guidance/definition-of-relevant-building:

- Low-rise buildings are assumed to be less than 11 m in height*

- Mid-rise buildings between 11 m – 18 m*

- Very tall buildings of 30 m and above.*

*Height of top storey measured from the upper floor surface to ground level on lowest side of building.

Prescriptive design solutions, sometimes referred to as fire resistance period compliance, essentially combine specific and defined material combinations and aligned test evidence to meet the regulatory objectives. Examples of timber solutions and assessment are introduced throughout this website. The applicability of solutions will need to be verified – in the UK generally by testing.

For reaction-to-fire performance, some timber material combinations can be used without the need for further testing. It is important to recognise that every available timber solution will need to be verified for the specifics of the application on a project. Test evidence and performance achieved is inextricably linked to test conditions and these need to match the application (for example the mounting of materials, gaps or even colours and finishes).

In applications where standardised approaches are not feasible, whether as a function of the amount of combustible materials, layout or occupation, the requirements of the project and complexity of application, the prescriptive solutions will be too limiting to be able to demonstrate that fire safety objectives are met. This will require a performance-based approach. In this approach, evidence of performance is generated based on the functional requirement by testing, calculation or modelling to confirm performance meets requirements.

Note 1: Performance-based design (PB)

Note 2: Subject to the insurance requirements of the project

Note 3: The most appropriate design approach will depend on building type and use. In this application, a combination of design approaches is common

Prescriptive design

This requires following performance requirements or recommendations specified within a guidance document, e.g. maximum travel distances, periods of fire resistance etc. In the UK, this can be achieved by following Statutory Guidance (such as the Approved Documents in England and Wales, Technical Handbooks in Scotland, or Technical Booklets in Northern Ireland). Alternatively, British Standards such as BS 9991 Fire safety in the design, management and use of residential building, Code of practice and BS 9999 Code of practice for fire safety in the design, management and use of buildings may be followed.

The designer should review the proposed building and its use at concept stage to identify whether the prescriptive guidance available will be suitable.

BS EN ISO 13943 Fire safety – Vocabulary defines “prescriptive regulation” as: “regulation in which the means and approach for compliance are completely or mostly specified”.

Although the above definition is specifically about regulation, it helps explain a prescriptive approach.

Performance-based design

A design developed from first principles with objectives defined, and an assessment undertaken to demonstrate the achievement of those objectives.

BS EN ISO 13943:2017 defines “performance based design” as:

“design that is engineered to achieve specified objectives and performance criteria”.

For example, where a prescriptive design is adopted, the periods of fire resistance tabulated in the guidance for a specific building occupancy type and height could be followed; whereas a performance-based design could undertake an assessment of the fire behaviour within a fire compartment and the resulting load-bearing capacity of the structure.

The Regulatory regime in the UK permits performance-based design for nearly all aspects of fire safety in buildings, except for specific limitations on the use of combustible materials as part of external wall construction in England and Wales, see Reaction to fire performance – external surfaces.

Prescriptive guidance reduces approvals risks and provides clear guidance for manufacturers as to what product standards must be achieved.

A performance-based design will always include parts of the prescriptive approach, i.e. a performance-based approach to the fire ratings for the structure of a building will also include the prescriptive requirements for means of egress.

Approval process

Each of the four nations of the UK has a different approval process and approval bodies. In Scotland and Ireland, the Building Regulations are enforced by Building Control Officers employed by local councils. In England and Wales, Local Authority Building Control Officers or licensed Approved Inspectors may be used, the latter being private entities – although, under the Building Safety Act, the building regulator is likely to determine who will be the approving body for high risk buildings.

Each nation has produced guidance for the building regulations approval process:

| Nation | Guidance |

| England | Manual to the Building Regulations, MHCLG (2020) |

| Northern Ireland | http://www.buildingcontrol-ni.com/advice-and-guidance |

| Scotland | The Scottish Building Standards: Procedural Handbook, Building Standards Division (2019) |

| Wales |

https://gov.wales/sites/default/files/publications/2019-06/building-regulations-approval.pdf The guidance referenced above for England is also relevant to Wales. |

Fire safety strategy

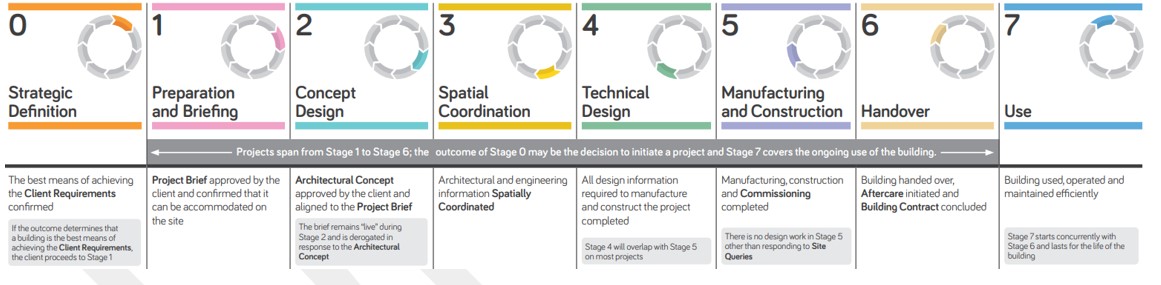

In the UK, projects commonly follow the RIBA Plan of Work, made up of eight stages (0 to 7) as shown here:

Figure 2: RIBA Plan of Work 2020

Consultation with the Statutory Authorities should begin at RIBA Stage 2. At this early stage, the design will be focused on the massing of the building, the external envelope, site layout, and possible materials.

The RIBA Plan of Work recommends the route to Building Regulations compliance be agreed at Stage 2. This is particularly important where a performance-based, rather than prescriptive guidance approach, is to be developed. If the performance objectives are not defined at an early stage, the design cannot be progressed without significant risk.

Early engagement with the statutory authorities allows potential challenges to be identified and resolved as the design develops through Stages 3 and 4. Consultation with the statutory authorities should continue through RIBA Stage 3, as the internal layout and fire safety strategy are developed, and Stage 4, when the technical design is being completed.

In summary:

- RIBA Stage 2 – Undertake fire safety strategy, or for complex and high risk projects, a Qualitative Design Review (QDR) – (see figure 3) and agree with statutory authorities what elements, if any, shall be developed following a performance-based design and the performance objectives;

- RIBA Stage 3 – Agree assessment method, input parameters, and scenarios/design details to be assessed with statutory authorities. This could also include scoping studies such as hand-calculations or qualitative assessments to provide confidence in the likely outcomes of the detailed assessment; and

- RIBA Stage 4 – Undertake detailed analyses and prepare report/results to demonstrate performance objectives are satisfied for submission to Building Control.

Supporting guidance

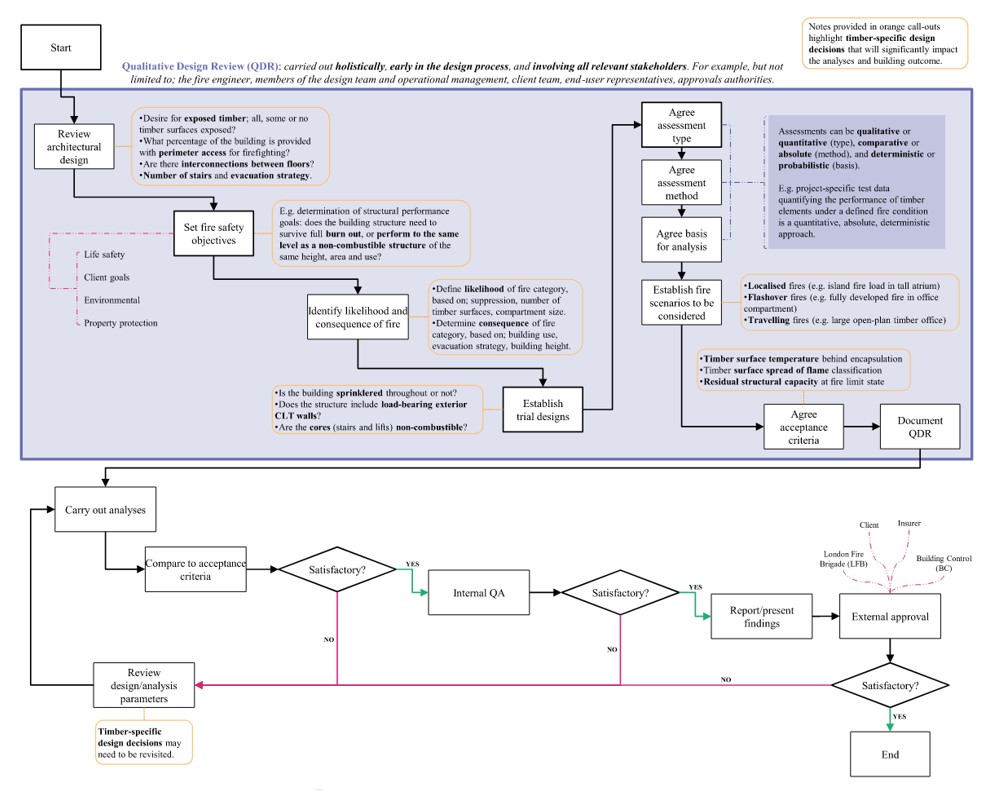

For high rise and complex timber projects, a Qualitative Design Review (QDR) is commonplace. The QDR process is used for a structured qualitative assessment of the proposed building fire safety strategy and is provided in the British Standard BS 7974 (Application of Fire Safety Engineering Principles to the Design of Buildings – Code of Practice). The QDR process adopted on large, complex and high-rise projects would commonly call upon the knowledge and experience of a competent fire engineer and includes feedback from other design team members and the building client team and operators.

For structural timber buildings used in low to medium rise construction, the in-depth and complexity of a QDR process may not be appropriate. Review and early exchange with stakeholders, such as the fire brigade, is recommended and industry guidance can guide on approach and scope to be considered at the outset.

Qualitative design review process (Technical level 1)

Figure 3: Qualitative Design Review process based on BS 7974 and BS 9999

Scope of prescriptive-based design for structural elements

In prescriptive design, evidence of fire resistance performance (generally 30, 60, 90 and 120 minutes) is combined for the building, i.e. for wall, floor or roof. The adequate performance of the build-ups, where required subject to loading, is demonstrated either by testing representative build-ups, suitable comparison elements, or by calculation, with methods outlined in BS EN 1995-1-2. In the UK testing of representative components is generally preferred.

Similarly, reaction-to-fire evidence is established through testing to standards or with standardised certified without further testing (CWFT) set-ups, see Reaction to fire performance – internal surfaces. For some projects, non-standard test evidence can be provided, for example a room test, which links measured performance to fire resistance requirements and informs the design team and third party checking bodies.

This type of design to be accepted when the structure is assumed to remain stable for the required time, with limited internal fire spread, to facilitate occupant escape and rescue service safety to enable efficient intervention.

Timber elements and build-ups provide fire resistance in a number configurations:

- Exposed timber structural elements of dimensions so that char layers formed upon fire exposure do not contribute to load-bearing ability for the required period of time (see Separating timber wall and floor assemblies): the exposed timber is checked for strength after a charred layer and zero strength zone have been accounted for.

- Partially protected timber elements, where protective layers shield the timber element from effects of heat for certain periods of time: a commonly adopted protection layer is gypsum-based boards. Here fire resistance testing to EN1363 (in the UK also BS476) series of tests is commonly adopted. Testing of representative build-ups provides values for loadbearing capacity (‘R’), fire break-through (‘E’) and a temperature rise (‘I’) on the surface remote from the fire exceeding 180 degrees or an average of 140 degrees over several points.

- Encapsulated timber elements, where all timber elements are enclosed and shielded from the fire for the required fire resistance period – K classes (see Separating timber wall and floor assemblies): here protection is provided to the underlying structure/substrate to mitigate the onset of pyrolysis for the full duration of the relevant fire resistance period. This is commonly addressed through the specification of linings achieving demonstrated k2 classifications per BS EN 13501-2. Where a lining is specified for the purposes of encapsulation, it should be shown that the interface temperature between the combustible substrate and lining (and away from fixings) remains below 200° C (indicating the decomposition of hemicellulose) for the duration of the relevant fire resistance period. Whilst mechanically fixed lining solutions have been tested, in the UK this needs to be reviewed, with product test data and associated thermocouple readings available to ensure applicability. It is important to evaluate whether available test data will be suitable for the application. Where encapsulation is adopted as part of the overall fire safety strategy, the premature failure of any protective lining must be carefully reviewed to ascertain whether there is risk of disproportionate damage/collapse of the overall structure.

Scope of performance-based design for structural elements

Designers can turn to many guidance documents for practical advice on how to undertake performance-based designs in general and can apply the principles to buildings incorporating timber.

A non-exhaustive list of performance-based design guidance documents is provided below:

- SFPE Handbook of Fire Protection Engineering, Fifth Edition, Society of Fire Protection Engineers, 2016;

- CIBSE Guide E, Fire safety engineering, 4th Edition, CIBSE, 2019; and

- BS 7974 Application of fire safety engineering principles to the design of buildings. Code of practice, British Standards Institution 2019.

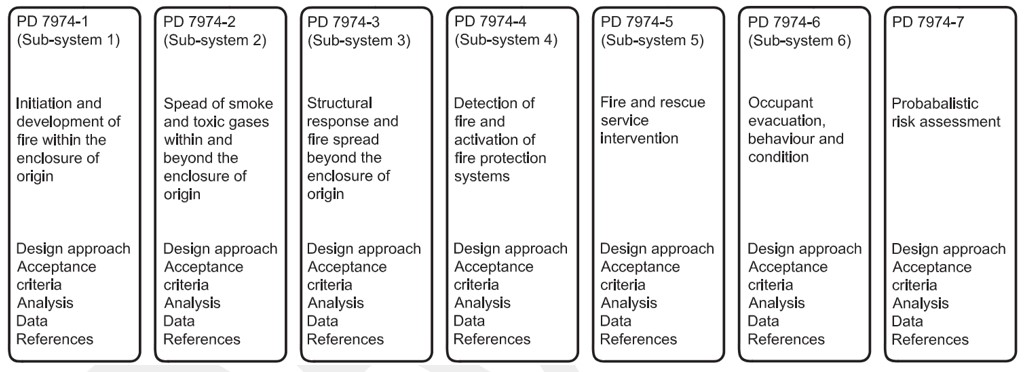

As BS 7974 is referenced within statutory guidance in the United Kingdom when undertaking performance-based design, it is presented in more detail here.

Excerpt from BS 7974:2019 (Technical level 1)

When undertaking a performance-based design, the designer must ensure that any analyses and associated analyses or use of empirical relationships are valid for their intended application.

BS 7974 is supported with seven published documents (PD 7974 Parts 1 – 7):

Figure 3: Excerpt from BS 7974:2019

Where a performance-based design is being adopted, it is not always necessary to do the entire design from first principles. As part of the holistic QDR process, there may be elements of the design for which prescriptive guidance may be suitable and supplemented by a performance-based design.

Where mass timber is introduced to a compartment, if not fully encapsulated, it can contribute fuel to a fire and provide a route for fire to spread within the building, over its exterior and to other nearby buildings. Further, where not encapsulated, the structural fire resistance will be impacted, as the timber chars and adds combustible fuel. The inclusion of mass timber can also have an impact on fire and rescue service intervention.

This section and the later sub-sections are concerned with the fire dynamics for compartments containing mass timber and the structural response; therefore, PD 7974-1 and PD 7974-3 are relevant. See Technical level 1 below.

When setting the scope of a performance-based design for timber structural elements, there are three aspects to consider:

- Compartment fire dynamics, including the additional fuel from a timber structure when not fully encapsulated;

- The structural response of the timber elements; and

- The impact of the exposed timber on external fire spread, both vertically up the exterior face of the building and to any neighbouring buildings.

These are described in detail in Technical level 1 below.

Compartment fire dynamics (Technical level 1)

As timber is an organic material, it is combustible. The inclusion of timber structural elements within a building adds fuel load to the fire compartment where the timber is not adequately protected from any ignition sources.

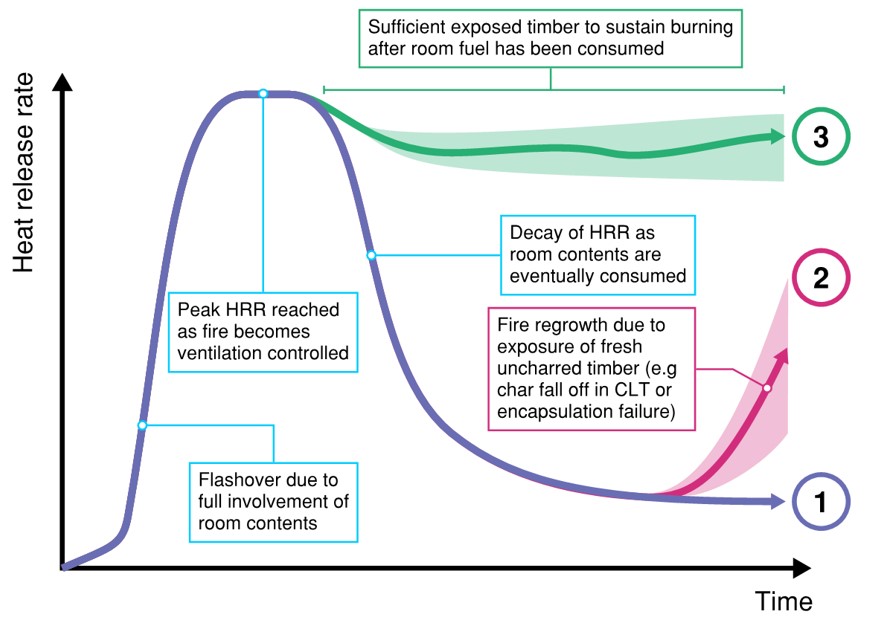

Figure 4 outlines three possible fire scenarios for compartments containing mass timber:

-

- Fire growth, followed by a quasi-steady period with constant heat release rate and then decay. In this scenario the amount of exposed timber is limited such that re-radiation does not sustain flaming combustion. Smouldering combustion may continue.

- As per the above, if the adhesive between the timber layers softens and the charred lamellae fall off, cyclical behaviour is observed as the fire regrows until the char layer develops again. This behaviour can also be observed where encapsulation fails;

- Following the initial growth, the fire maintains a quasi-steady heat release rate and does not decay, due to the amount of timber exposed.

Figure 4: Heat release rate

From the above therefore, scenarios 2 and 3 present the greatest risk – as a fire could sustain flaming combustion until the entire structural timber has been consumed. Scenario 1 is akin to the fire dynamics within a compartment constructed from non-combustible materials and only the moveable contents are combustible.

Some regulators might request specific consideration to be given in the design to scenarios 1 and 2, referred to as ‘burnout’ especially for taller and more complex buildings. For further information see Östman, B and Buchanan, A, 2022 Fire Safety Use of Wood in Buildings Global Design Guide CRC Press ISBN 9781003190318, specifically Chapter 3, p 94-95.

It is also important to note that whilst flaming combustion may cease, timber can continue to smoulder, see Reaction to fire performance – external surfaces.

Structural response (Technical level 1)

A performance-based design needs to assess how the structural timber that is exposed, or not fully encapsulated, responds to a fully developed fire. The performance-based design is to be evaluated for a number of credible design fires, where the design fire has to take into account the additional fuel of the exposed structural timber. Each design fire will be influenced by the exposed structural timber, given that the combustion process of the timber’s charring converts the mass into fuel. The design fires evaluated will need to be based on a range of differing initial fixed fuel types and varying ventilation scenarios.

Of importance for mass timber structures is the decay phase of the fire, given the exposed mass timber will result in a longer fire decay when compared with a non-combustible structure, and charring will still occur during this decay phase.

An approach to defining fire decay should be agreed with the statutory authorities, and this may include a minimum heat release rate (e.g. a fire less than 1 MW), or a compartment temperature (e.g. less than 100o C), or a temperature in the mass timber (e.g. less than 100o C). The design for charring is to be carried out for the period of fire ignition through to the agreed decay point.

The structural assessment is to include analysis of load-bearing capacity, maximum deflection (where relevant), single element failure, connections and impact on encapsulation.

External fire spread (Technical level 1)

Exposed timber, or timber which is not fully encapsulated, within a compartment can contribute to a fire as fuel. Depending on the number of openings, there may be inadequate ventilation for the fuel to burn within the compartment. Therefore, the pyrolysis gases leave the compartment and burn outside the opening where oxygen is present. This can produce large flames protruding from a window that result in an external heat flux and the risk of fire spread to neighbouring buildings 1, 2 . Further, external flaming increases the risk of vertical fire-spread up the face of the building, spreading to the compartment above – known as leapfrogging.

Where exposed timber is included as part of the building structure and is located at the ceiling, the timber can cause increased external flaming due to the position of the fuel relative to the window.

The designer is therefore required to consider the fuel load and ventilation to the compartment, and the location of the compartment within the building, as well as the buildings and other infrastructure near it. The designer then identifies what safety measures are needed, e.g. if suppression is needed to control fire growth, if openings need to be limited, or fire-resisting construction is to be provided to limit fire spread between floors and to neighbouring buildings. For some buildings more than one of these measures may be required to achieve the fire safety objectives.

Traditional evaluation methods such as BR187 External fire spread: building separation and boundary distances (https://www.brebookshop.com/details.jsp?id=327394) may not be sufficiently conservative to capture the extent of external flaming observed with extensive exposed structural timber.

1 Heat fluxes to a façade resulting from compartment fires with combustible and non-combustible ceilings; Alastair Bartlett, Angus Law, Robert Jansson McNamee, Jochen Zehfuss, Siyimane Mohaine, Christophe Tessier, Luke Bisby; FSF 2019 – 3rd International Symposium on Fire Safety of Facades Paris, France, September 26-27, 2019

2 Exposure from mass timber compartment fires to facades; Johan Sjöström, Daniel Brandon, Alastair Temple, Emil Hallberg, and Fredrik Kahl; RISE, 2021

Encapsulation of timber elements

European harmonised standards (Technical level 1)

Within the European harmonised standard framework, for periods of fire resistance of up to 60 minutes, encapsulation can be tested to EN 14135 and classified to BS EN 13501-2. For a k2 covering, the following performance criteria are defined in Clause 7.6.4.2 of BS EN 13501-2:

- There should be no collapse of the covering or parts of it.

- During the test, the mean temperature measured on the lower side (i.e. between the encapsulation and the timber) of the substrate shall not exceed the initial temperature by more than 250° C, and the maximum temperature measured at any point of this side shall not exceed the initial temperature by more than 270° C.

- After the test there shall be no burnt material or charred material at any point on the substrate.

The harmonised European standards do not allow for classification of k2 coverings beyond 60 minutes. Therefore, where a period of fire resistance greater than 60 minutes is required, there will need to be an assessment carried out by an ‘EGOLF’ member (European Group of Organisations for Fire Testing, Inspection and Certification). This should be supported by an extended test to EN 14135 with duration at least equal to the required fire resistance.

Calculation methods and approaches

Prescriptive

Within the United Kingdom, BS EN 1995-1-2 may be used for the fire resistance design of solid timber, LVL, and glulam elements of structure. Further, BS EN 1995-1-2 provides guidance for the design of connections for up to 60 minutes’ fire resistance.

BS EN 1995-1-2 does not cover the design of mass timber structures, such as cross-laminated timber, which is likely to be outside of the standard fire curve that the EN 1995 design process is focused on. The prescriptive design approach may be applicable for mass timber, and a design fire curve derived for the structure; alternatively the BS EN1995-1-2 may be used to derive encapsulation measures through its calculation process of adopting non-combustible protection layers.

The United Kingdom National Annex to BS EN 1995-1-2 currently precludes the use of the following informative annexes within BS EN 1995-1-2:

- Annex A Parametric fire exposure

- Annex B Advanced calculation methods

- Annex D Charring of members in wall and floor assemblies with void cavities

- Annex E Analysis of the separating function of wall and floor assemblies

UK users are advised to check status on this regularly, as the Eurocode update will conclude and the National Annexes will be re-issued. Since the last publication additional research has been undertaken that will be used to adjust the UK approaches above.

Performance-based

Where advanced calculation methods, such as finite element analyses, are adopted and do not follow prescriptive guidance, the designer must ensure that the method has been validated and verified for the arrangement in which it is being applied.