Reaction to fire performance – external surfaces

To search all text on this page

On Windows – Press Ctl+F

On Mac – Command+F

This site is suitable for a wide range of users, with technical information

levels 1 and 2 available on closed toggles

Technical level 1 Technical level 2

External walls – international views

- International methods

- Europe

- Test methods for facades used in Europe

- North America

Introduction

The external layer of a building typically comprises the external wall and the facade, or external surface. Timber is used in all layers of the external build-up, dependent on the height and type of building. The permitted use of timber in these applications varies from country to country. The overriding fire safety objective for these components is to limit the spread of fire within and across the building and to adjoining buildings.

In the UK specifically, regulatory changes following the Grenfell fire limit the use of combustible materials for certain building heights. This remains an evolving situation and the reader is referred to the statutory guidance and national legislation to ascertain the requirements for their specific application.

Each country in the UK has statutory and regulatory requirements both for the external walls and external surface of buildings. To provide guidance on how to meet the legal requirements, each country publishes and maintains a set of guidance documents which, for those buildings that are in the scope of the guidance, can be used as a means to demonstrate compliance with the legal requirements by following the prescriptive guidance. Each country has a set of different, but often similar, requirements and guidance documents:

- England and Wales: Approved Documents

- Scotland: Technical Handbooks

- Northern Ireland: Technical Booklets

Here information is provided on general principles, methods of assessment and a guide on international practices, as well as specific information on external walls. Extensive work on the behaviour of timber facades has been completed and compliant standardised layouts and solutions proposed, see for example Swiss research in the 2000s and a paper on facade/external wall detailing published in 2021 and available here.

It is important to note that this information needs to be seen in the context of local, national regulations and performance requirements and cannot be translated literally into UK practice. However, the availability of information of this kind can provide some guidance on available options, especially for designers, clients and stakeholders looking to assess the feasibility of a timber-based facade solution for their project. In the UK it is most likely that proposed solutions will need to be tested, and a section is introduced below overviewing the common test approaches across the world in relation to fire performance of facades, for timber and other materials.

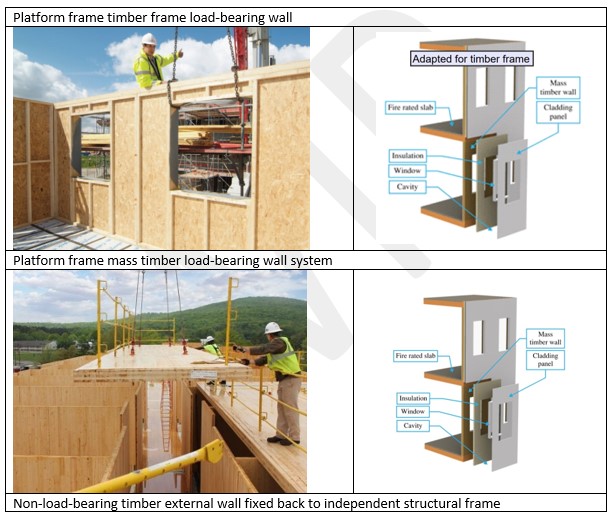

Some typical UK structural timber wall systems, including key components, are shown below:

Typical structural timber wall systems

Figure 1: Examples of timber external wall constructions

Typical timber facades

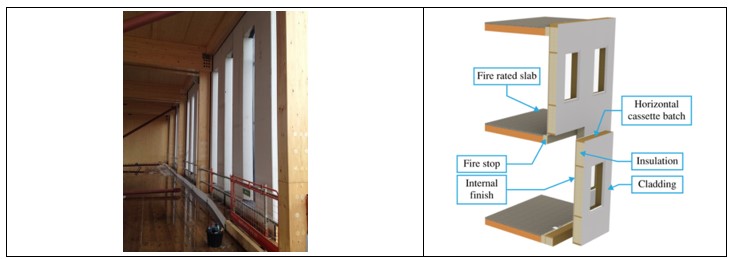

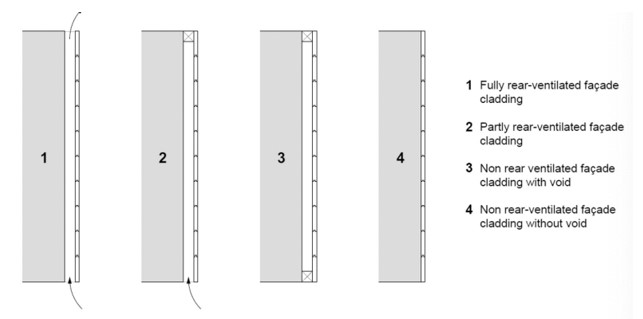

External walls and surfaces can present a route for fire to spread through the wall to adjacent buildings; over the external surface to adjacent compartments; or unseen through cavities within the external wall and between external surface and wall.

Preventing and limiting fire spread are key, and robust detailing and execution are of paramount importance. The detailing is dependent on the type of facade and its interaction with the external wall, whether made of wood or not. All facades, and especially fully ventilated facades, require detailed fire stop design and execution – see also Cavity barriers and fire stops. There has been a number of studies to provide guidance on tested timber configurations, and for each project a detailed assessment, generally supplemented by testing in the UK, is required. Experimental work has shown that the spread of fire can be effectively limited by means of horizontal fire stops, breaking continuous wood cladding and ventilation cavities. Execution and quality control are key to achieving tested performance in wood, as well as other facade materials. See Cavity barriers and fire stops.

Figure 2: Fire safety in wooden facade design

Source: Structural means of fire safety wooden façade design, Engel and Werther-Fire Technology, 2001

External walls – international views

This risk can be evaluated by the reaction-to-fire performance of the facade cladding, but in some countries, facade systems must also be tested in a specific facade test rig, where the spread of fire over one or two storeys above the storey of fire origin must be evaluated.

International methods (Technical level 1)

An overview of the systems used in prescriptive building regulations in different parts of the world is given in technical level one below. The prescriptive requirements are usually based on fire testing.

International fire test methods for facade claddings are summarised in the table below.

International full-scale facade fire tests (simplified after White and Delichatsios, 2014)

| Test standard | Country used | Test Scenario | Geometry of test rig |

Fire source |

| ISO 13785 Part 1:2002 |

International | Flames emerging from a flashover compartment fire via a window | Two walls in a corner “L” arrangement | Series of large perforated pipe propane burners. Total peak output 120 g/s (5.5 MW) within standard fire enclosure. |

| NFPA 285 | USA | Flames emerging from a flashover compartment fire via a window |

One fire source opening One wall |

Room burner increasing from 690 to 900 kW over 30 min test period, and window burner ignited 5 min after room burner and increasing from 160 to 400 kW over remaining 25 min test period. |

| CAN/ULC S134 | Canada | Pellet fire located directly against the base of a re‐entrant wall corner |

One fire compartment opening One wall |

Four 3.8 m long linear propane burners. Total output 120 g/s propane (5.5 MW) |

| FM 25 ft high corner test |

US/ International |

Pellet fire located directly against the base of a re‐entrant wall corner | Two walls in a corner “L” arrangement. Ceiling over top of walls |

340 ± 4.5 kg crib located in corner 305 mm from each wall. Ignited using 0.24 L gasoline at crib base. |

| FM 50 ft high corner test |

US/ International |

Flames at base of small section of facade | Same as FM 25 ft test | Same as FM 25 ft test |

Europe

Some European countries also use the reaction-to-fire classes (EN 13501-1) for facades, while other countries have different requirements (Östman et al, 2010). A review was presented (Anderson et al, 2017), but there is at present no European harmonised solution for assessing and quantifying the fire performance of timber facades, so national approaches have to be used, and the acceptance of wooden facade claddings varies from country to country.

Development work is continuing (Anderson et al, 2021). The goal is a European approach to assess the fire performance of facades, which might take 5-10 years to achieve. A review of the present situation in Europe is available (Östman and Mikkola, 2018) and methods (full or medium scale) used in Europe are shown in the table in technical level 1 below (Boström et al, 2018).

Structural fire protection and fire stops are fundamental requirements when facades are used as the outer surface of external walls of multi-storey buildings (regardless of the material used). The goal is to prevent uncontrolled fire spread on the surface and in ventilation cavities (if present) of the external wall for a required period.

Table 1: Fire test methods for facades used in Europe (Technical level 1)

(Anderson et al, 2017; Boström et al, 2018)

| Country | Test method | Scope | Application | Scale | Configuration |

| Austria, Switzerland |

ÖNorm B 3800-5 | Simulates a fire from a window burnout of an apartment and the flame height in the second floor above the fire floor | Ventilated and non-ventilated facades, ETICS etc | Full scale | Vertical wall and a right angle wing |

| Belgium | Lepir 2, BS 8414-1, BS 8414-2 or DIN 4102-20 |

See other countries | All facade system for high-rise and mid-rise buildings | Full or Medium scale | See other countries |

| Czech Republic |

ISO 13785-1 | Reaction to fire test | Medium scale | Right angle, return wall | |

| France | Lepir 2 | Fire behavior of building facades with windows. Includes classification criteria | All facade system incl. windows | Full scale | Single vertical wall |

| Germany, Switzerland | DIN 4102-20 | Complementary test of cladding systems (each part has to be low flammable) | For classification as low flammable system | Medium scale | Two wings (corner) |

| Germany | Technical regulation A 2.2.1.5 | Test for ETICS and EPS insulation | Fire performance for fire outside the building | Full scale | Two wings (corner) |

| Hungary | MSZ 14800-6:2009 | Fire propagation test for building facades | No provisions for extending the test results | Full scale | Single wall with two openings |

| Poland | 1. PN-B-02867:2013 | Determination of fire behaviour of facades without windows | All facade systems | Medium scale | Single vertical wall without openings |

| Slovakia | ISO 13785-2 | Reaction to fire test | All external thermal insulation systems | Full scale | Right angle, return wall |

| Sweden, Norway, Denmark |

SP Fire 105 | Reaction to fire of external wall assemblies | External wall assemblies and facade claddings added to an existing wall | Full scale | Single vertical wall |

| Switzerland | Prüfbestimmung für Aussenwand-bekleidungssysteme | Fire behaviour of external wall covering systems, when exposed to fire from a simulated apartment fire with flames out of a window | Linings and surface coating used on exterior walls, incl. elements with limited application area | Full scale | Single vertical wall, no wing |

| UK, Republic of Ireland | BS 8414-1 and BS 8414-2 | Fire performance of external cladding systems | The system tested | Full scale | Right angle, return wall |

North America (Technical level 1)

In the United States, the standard NFPA 285 describes a test method intended to evaluate the capability of exterior wall assemblies constructed using combustible materials to resist vertical and, to some extent, lateral flame propagation over the exterior and interior faces and within the core of the assembly. The apparatus consists of a two-storey structure with an open window in the lower compartment. Two gas burners are used to create the exposing fire. The main burner is located inside the first floor burn room and is used to develop a temperature-time curve that is comparable to that prescribed in the fire resistance test standard ASTM E119. A second burner is located inside the window opening, so that flames hit the window head, which is the most vulnerable part of the exterior wall assembly for flame penetration into the core. In 2019 the scope of the standard was expanded from non-combustible buildings (steel and concrete) to all construction types, including mass timber buildings.

The building codes in the US specify a minimum separation distance between adjacent buildings based on the assumption that exterior walls are covered with wood siding (cladding) and that the minimum heat flux for piloted ignition of the siding is 12.5 kW/m2. The test standard NFPA 268 is used to determine the piloted ignition threshold of alternative siding materials and verify that it does not exceed 12.5 kW/m2. Wood siding (cladding) is assumed to meet these requirements and does not need to be tested.

In Canada, the standard CAN/ULC-S134 is the test method used to evaluate the fire performance of exterior wall systems. The Canadian method is conceptually similar to that described in NFPA 285. However, the NFPA 285 test wall is shorter 4×5.33 m versus 5×7 m, and the heat flux to the exterior wall from the flame and plume above the window is significantly higher, but of shorter duration in the Canadian test (average 45 kW/m2 over 15 minutes at 0.5 m above the window versus average 25 kW/m2over 30 minutes at 0.6 min). Exterior wall designs with FRT wood claddings can pass the test but the wood first needs to be exposed to accelerated weathering according to the methods described in ASTM D2898.

Bibliography (Technical level 2)

Anderson, J., Boström, L., Jansson, R. (2017) Fire safety of facades, SP Rapport 2017:37.

Anderson, J., Boström, L., Chiva, R., Guillaume, E., Colwell, S., Hofmann, A., Tóth. P. (2021) European approach to assess the fire performance of façades. Fire and Materials, 45:5.

ASTM D2898 Standard Practice for Accelerated Weathering of Fire-Retardant-Treated Wood for Fire Testing, ASTM International, West Conshohocken, PA.

ASTM E119 Standard Test Methods for Fire Tests of Building Construction and Materials, ASTM International, West Conshohocken, PA.

Boström, L. et al (2018) Development of a European approach to access the fire performance of facades, Final report. Project: SI2.743702-30-CE-0830933/00-14.

CAN/ULC-S134 Standard Method of Fire Test of Exterior Wall Assemblies, Underwriters Laboratories of Canada, Toronto, Canada.

EN 13501-1 Fire classification of construction products and building elements – Part 1 Classification using data from reaction to fire tests, CEN European Committee for Standardization, Brussels.

NFPA 268 Standard Test Method for Determining Ignitability of Exterior Wall Assemblies Using a Radiant Heat Energy Source National Fire Protection Association, Quincy, MA.

NFPA 285 Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components, National Fire Protection Association, Quincy, MA.

Östman, B., Mikkola, E., Stein, R., Frangi, A., König, J., Dhima, D., Hakkarainen, T., Bregulla, J. (2010) Fire Safety in Timber Buildings – Technical Guideline for Europe, SP Report 2010:19, SP Trätek, Stockholm, Sweden.

Östman, B., Mikkola, E. (ed) (2018) Guidance on Fire Safety of Bio-Based Facades. Dissemination document N230-07 – COST Action FP 1404 | ETH Zurich.

White, N., Delichatsios, M. (2014) Fire Hazards of Exterior Wall Assemblies Containing Combustible Components, Document Number: EP142293, Fire Protection Research Foundation.