Cavity barriers and fire stops

To Search All Text On This Page

On Windows – Press Ctl+F

On Mac – Command+F

This site is suitable for a wide range of users, with technical information

levels 1 and 2 available on closed toggles

Technical level 1 Technical level 2

Introduction

- Fire statistics

- Fires attended by type

Concealed spaces

- UK building regulations

Cavity barriers and fire stops

- Fire stop testing

Selecting products

- Overview of available products

Installation

- Modular construction

- Facade cavities

Introduction

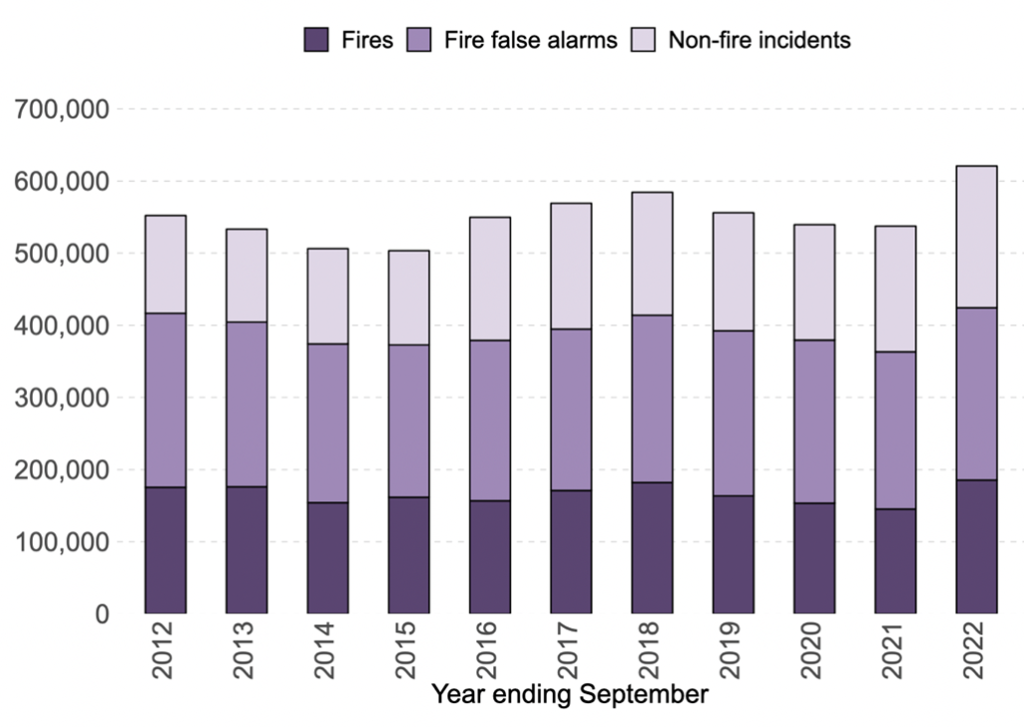

About 500 fires occur in England every day. Detailed data is recorded about all incidents attended by the fire and rescue services in England. Fire statistics are collected and collated each year, recording fire incidents, their causes, spread and consequences for all fires and all construction types . Fire brigades and others investigate some fires in more detail to learn and inform the review of effectiveness of fire safety provisions.

Figure 1: Incidents attended by the Fire and Rescue Services in England, in the year ending September 2022

The majority of fires in England occur in dwellings, as do most fire-related fatalities (276 in the year ending 2022). About a quarter of all fires are limited to the room of origin.

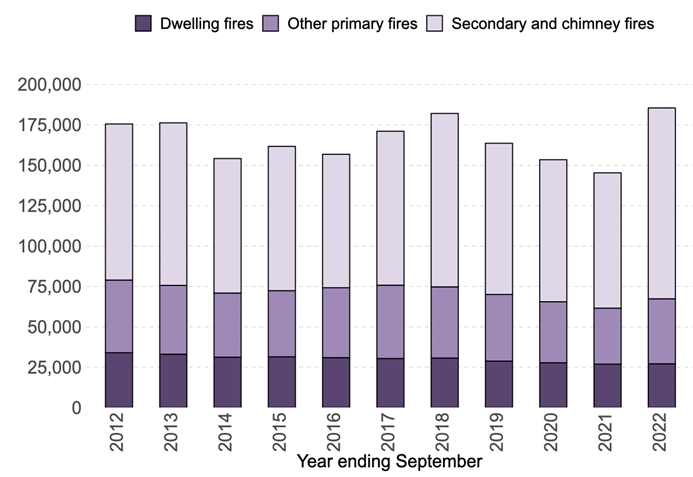

Figure 2: Total fires attended by type of fire, England (year ending September 21 to year ending September 22 (Source: FIRE0102)

Fire statistics (Technical level 1)

The fire statistics collated for the year end March 2022, concluded ‘nearly one third (30%) of dwelling fires had no fire damage, in around a third (33%) the damage was limited to the item first ignited and in roughly a quarter (24%) the damage was limited to the room of origin. The remaining 14 per cent of dwelling fires were larger fires, either “limited to floor of origin”, “limited to 2 floors”, “affecting more than 2 floors”, “limited to roofs and roof spaces” or the “whole building’. (FIRE0203).

Fires in purpose-built flats or maisonettes spread beyond the room of origin for

- high-rise (10+ storeys*), in 6% of all fires

- medium-rise (4-9 storeys*), in 8% of all fires

- low rise (1-3 storeys*), in 13% of all fires

The average area of fire damage in a dwelling fire was 14.2%. The average area damaged in other than (dwelling) buildings was 24.1%. The extent of damage has decreased over past years in all types of properties. Cooking appliances were the most common source of ignition for accidental dwelling fires, accounting for 45%, followed by ‘smokers’ materials.

For research and analysis of statistics and incident analysis dedicated to timber structures in specific, see Technical level 1 below.

Analysis of fire spread in timber structures (Technical level 1)

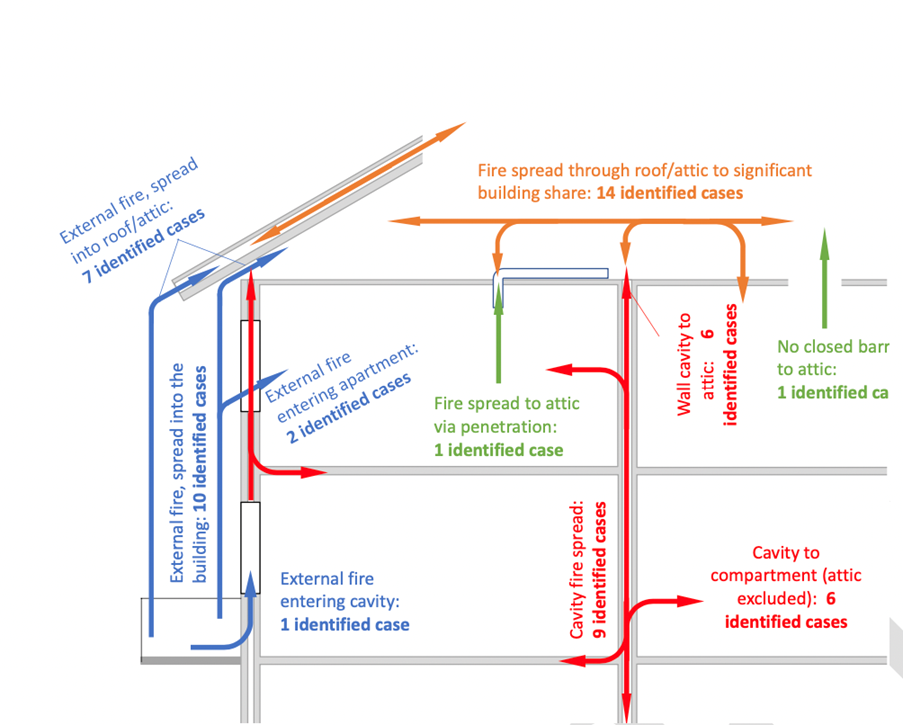

- Fire spread through the attic to large parts of the building.

- Fire spread along the facade entering the building (most commonly into the attic).

- Fire spread through wall and floor cavities.

In this study, attic fire spread was the most common path of significant fire spread, leading to fire in significant parts of the building. It should, however, be noted that a fire rarely starts in the attic (only in one of the 33 analysed fires started in the attic). Of the analysed fires, the most common ways the fire entered the attic are:

- external fires (commonly starting on a balcony) traveling through the eave

- cavity fires traveling to the attic

Figure 3: Identified paths of fire spread in fires that involved at least three fire compartments.

Source: Brandon D, Plathner, FV, Mikkola E, SAFITS – Statistical Analysis of Fires in Timber Structures. RISE report, 2021

The full study, including methods, qualification and limitations please read in full here.

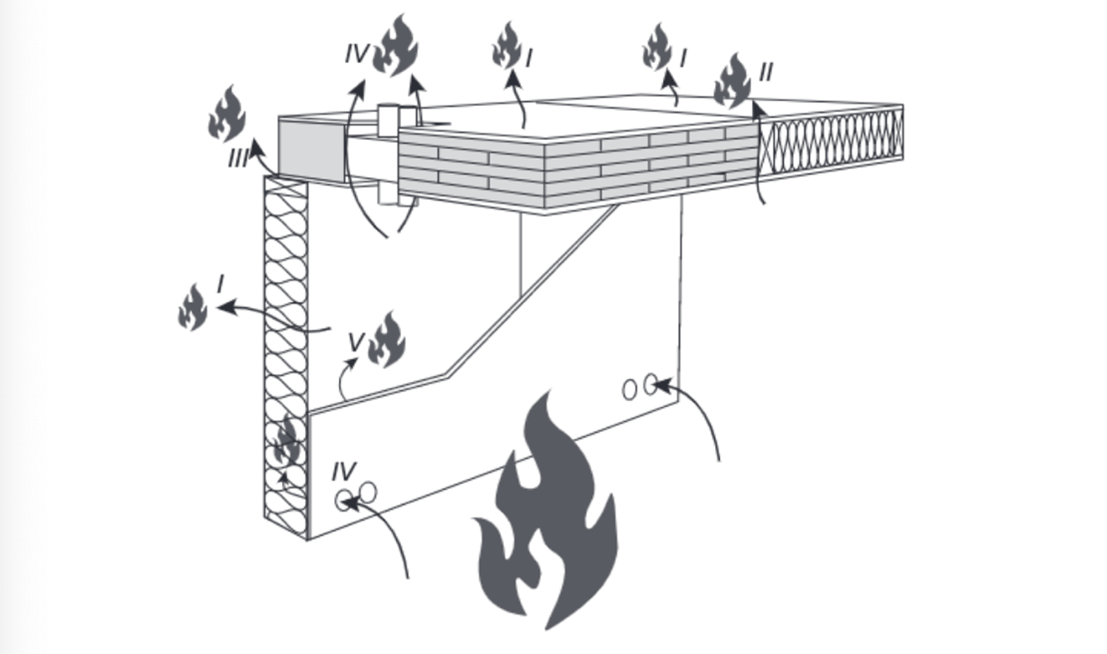

In the design of buildings, it is assumed that a fire will occur at least once in the lifetime of a building/structure. Other parts of this website have introduced concepts to contain and limit the spread of fire over internal and external surfaces (see Figure 4), constructional approaches to compartmentalising fires and how to ensure connections are protected where elements meet.

Figure 4

For these measures to deliver the overall fire safety goal – life safety for occupants and emergency services, and asset protection (see Fire safety in buildings) – fire and smoke must be contained within confined and dedicated zones, regardless of complexity of layout, use of materials and constructional detailing.

The main paths for fire and smoke to spread within a building are:

- Through separating elements, typically walls and floors of a building

- Through joints between separating elements to neighbouring compartments and associated construction tolerances

- Through junctions between building parts or intersections

- Through building services, penetrations and openings

- Through concealed construction cavities

Figure 5: Fire spread paths in and through timber structures

Source: Werther et al., 2020 redrawn for Global Design Guide, 2022

These fire spread paths must be considered and managed during design, installation and checked regularly during occupation of a building. In the UK, this is often referred to as ‘passive fire protection’.

This section focuses on managing fire spread in concealed spaces (fire spread paths III-V), specifically through the use of cavity barriers and fire stopping.

Reference to best practice for other fire spread modes is included at the end of the chapter and cross-linking to relevant information on the website is included there, too.

Concealed spaces

Every building has voids, cavities and service and installation shafts as part of its construction. Fire can spread unnoticed in these spaces away from direct view, circumventing compartmentation and other fire safety measures within a building. Fire and smoke can spread rapidly in these concealed spaces and pose risk to life of occupants and fire-fighters as well as widespread damage.

The management of the uncontrolled spread of fire and smoke relies on cavity barriers and fire stops where there are joints and penetrations between building elements and openings at interfaces. Construction tolerances and shrinkage, due to timber elements drying out over time, can also cause gaps which need to be managed.

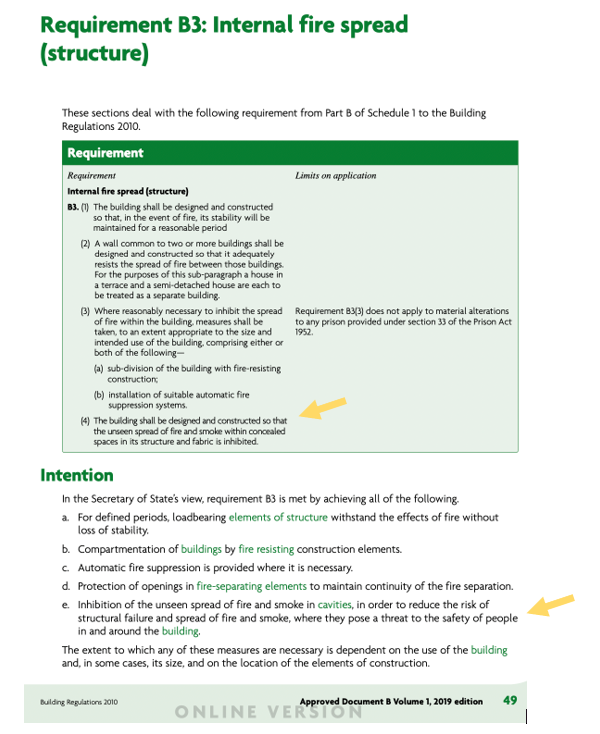

In the UK, building regulations provide requirements and guidance on the performance expectations of constructional features preventing unseen fire spread in concealed spaces.

UK building regulations (Technical level 1)

For England

- Approved Document B Volume 1: Dwellings

- Approved Document B Volume 2: Buildings other than dwellings

For Wales

- Approved Document B Volume 1: Dwellings

- Approved Document B Volume 2: Buildings other than dwellings

For Scotland

- Building Standards technical handbook 2020: domestic

- Buildings standards technical handbook 2020: non-domestic

For Northern Ireland

And further information here

Please ensure to access the latest available guidance.

Other helpful information can be found here

National Fire Chiefs Council

An extract (2019 edition, Approved Document B, Volume 1) shown below for illustration

Figure 6: Extract from UK Building Regulations, Approved Document B, requirement to inhibit the unseen spread of fire and smoke within concealed spaces.

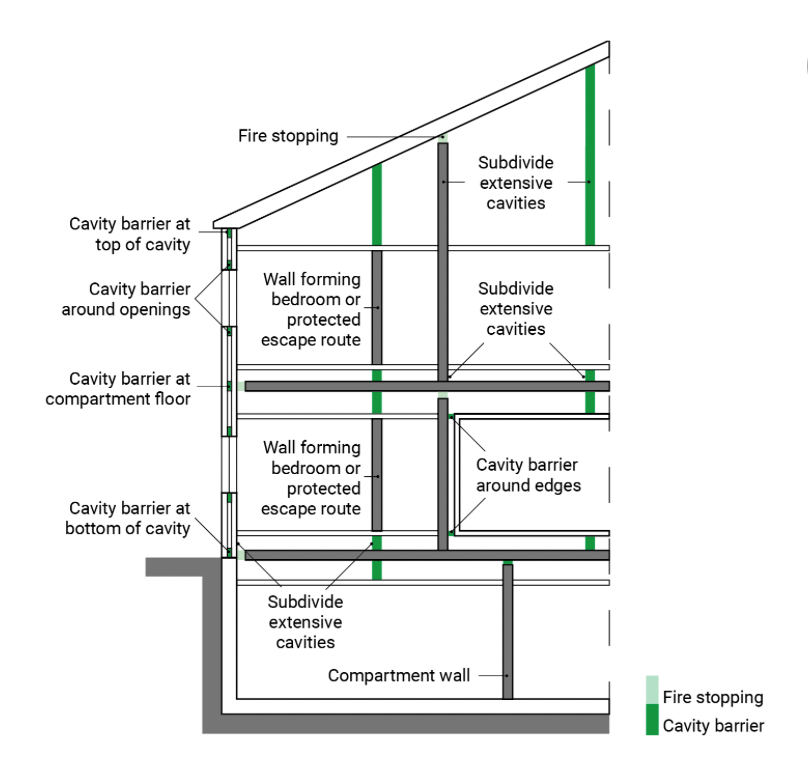

Cavity barriers and fire stops

Cavity barriers seal gaps in the structure of a building, providing a time delay to limit the spread beyond the barrier location, stop air being drawn through the cavity space and inhibit the passage of smoke. It is important to appreciate that a cavity barrier on its own can never be used to complete a fire compartment, but is an important part of delivering the compartmentation of a building.

Generally, cavity barriers are required:

- At the edges of cavities

- Around openings (windows, doors)

- At exit and entry points of services

- At the junction between any external cavity wall and every compartment floor and compartment wall

- At the junction between an internal cavity wall and every compartment floor or other wall or door assembly forming a fire-resisting barrier

- In roof spaces

- In external facades/cladding

- To protect escape routes

Figure 7: Taken from https://www.architectsjournal.co.uk/news/opinion/the-regs-how-to-make-buildings-fire-safe-with-cavity-barriers (Wilkinson, G. accessed 26 February 2023 12:25)

Fire stopping is used to provide continuity where gaps, imperfections, joints and small openings are present in fire-resisting elements of construction. Fire stop products are used to seal around small openings to close gaps and maintain the performance level of the wall or floor. As such, fire stopping will be expected to be of the same fire resistance as the element of structure to which it is fitted or attached.

Fire stop testing (Technical level 1)

- BS EN 1366-3 – Penetration Seals

- BS EN 1366-4 – Linear Joint Seals

On occasion it may be possible to demonstrate the effect of small gaps and joints using the methods provided in BS EN 1995-1-2 or other guidance documents but this will need to be discussed with the supply chain partners to ensure suitability and robustness of approach.

Any fire-stopping test must be relevant for the construction method being used, and variations between the as-built construction and the tested assembly may invalidate the application of the test results.

The installation of these fire safety and protection measures will be undertaken as the building process proceeds. Whilst this is the case for all buildings regardless of material, relevant considerations for timber buildings specifically are the focus here. This important aspect of ensuring fire safety in timber structures has been, and remains, a focus of research. Further reading on this is available, for example:

- Fires in cavities in residential buildings (2013) The performance of cavities barriers in external walls with combustible materials, NHBC Foundation, 2013

- Design principles for fire safe detailing in timber structures (2020), Werther N. et al World Conference of Timber Engineering Santiago, Chile

Selecting products

Cavity barriers are typically of non-combustible material, fitted within cavities horizontally at each floor and vertically at each party wall and around all openings. The specification and selection of cavity barrier systems is key to achieving fire safety but is not always firmly and reliably owned by a specific supply chain partner in the construction process; architects can defer the specification to the contractor; often key decisions are further deferred to the passive fire protection installer. Whilst generic systems and products are available to guide decisions, specific manufacturer and system type should be specified for a project. The installation needs to be approved by a competent review and sign off. As cavity barriers are typically hidden by the progress of the construction process, it is critical that final as-built and maintenance information is collated (see Information management in timber buildings).

The following will influence the product choice:

- Expected building movement. This could be due to future settlement, shrinkage, differential thermal expansion, deflection or sway of structural elements.

- Expected collapse or deformation of structures or surfaces that the cavity barrier is attached to.

- Services such as ducts or pipes.

Approved proprietary systems are available from many suppliers.

Overview of available products (Technical level 1)

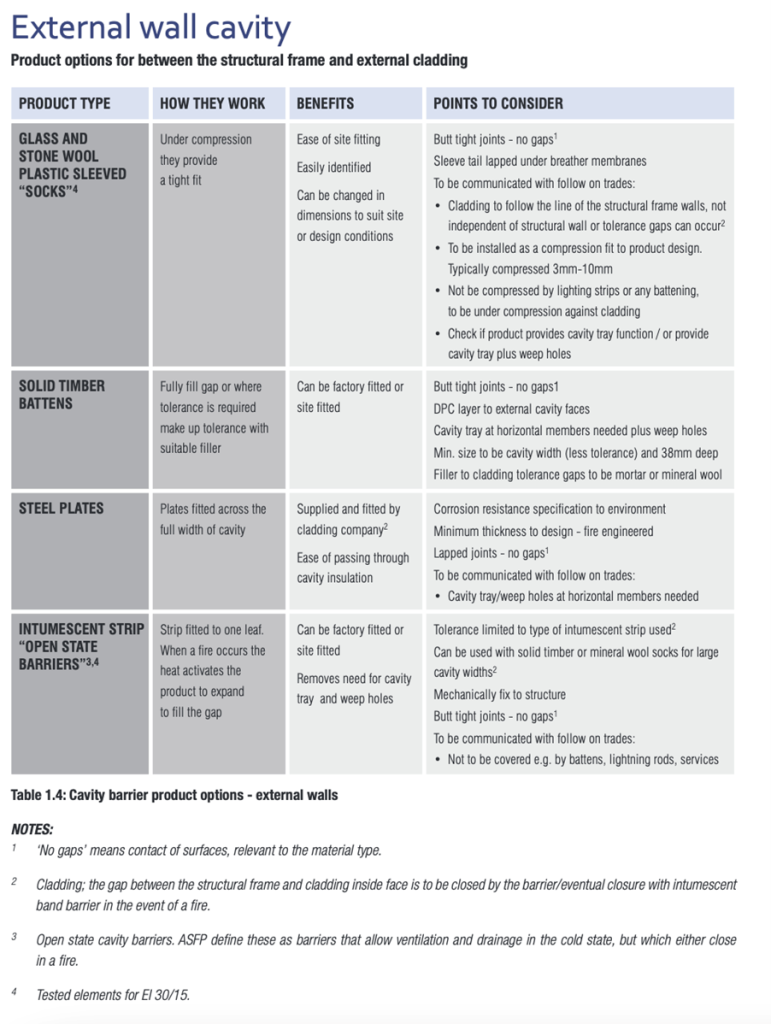

This for guidance only and shown as an example for external wall cavity solutions. Products and systems need to be adapted to the situation in which they are used, the overall fire safety strategy of the building, recommendations from specialist supply chain partners and design team considerations.

Figure 8: Extract from Structural timber in buildings fire safety in use guidance Volume 2 – Cavity barriers and fire stopping, STA, 2020

Any product chosen should be third party certified or CE marked and tested using relevant standards. Third-party standards such as RedBookLive are also available and often requested by insurers. This can increase confidence that the product is fit for intended purpose and manufactured to constant quality. Evaluation will consider

- Factory production control

- Initial type testing

- Appraisal of the product test and assessment against a technical schedule and scope of application

- Traceability of product

- Traceability through labelling

For a selection of third-party certified products see RedBookLive.

Other schemes and certification providers are available, here only shown as an example, see UKAS for more information and a full list of UK providers.

Installation

The quality of installation of cavity barriers is vitally important to providing compliant and performing cavity barrier and fire stopping solutions. Local fire and rescue services carry out inspections to help ensure buildings are compliant. The Association for Specialist Fire Protection (ASFP) is a leading advocate for driving standards across the industry, bringing focus to installation standards and quality of workmanship. The ASFP currently recommends the use of installers part of UKAS accredited/approved schemes.

Specific considerations for timber construction

In addition to guidance in the Building regulations, other publications are available: for example for lower rise construction, The Structural Timber Association Fire Safety In use guidance Volume 2 – Cavity barriers and fire stopping

As industry guidance evolves, every effort will be made to update the site to signpost additional information. Current information, linked above, covers functional requirements for cavity barriers in typical timber construction projects, roles and responsibilities and cavity barrier locations, detailing and ‘care points’ for the various supply chain interactions. It also highlights the use of competent and trained installers, as well as provision of photographic evidence of installed cavity barriers and firestops. This forms part of the STA Site Safe policy. For more information on quality assurance schemes available for timber construction, please see https://www.structuraltimber.co.uk/sta-assure/.

Modular construction

As construction techniques evolve and with increased use of timber solutions in modular construction techniques, attention to detail is key. Fire events have identified issues with the provision and quality of installation of fire protection products and systems in concealed spaces in this type of construction. These forms of construction introduce additional voids, cavities, and shafts into buildings and where modular construction is employed cavities between modules must be carefully considered, designed and managed.

For further information see Fire Safe Use of Wood in Buildings. Global Design Guide.

Facade cavities

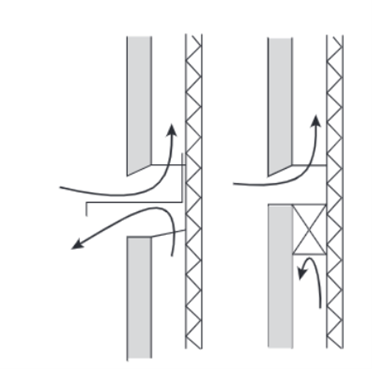

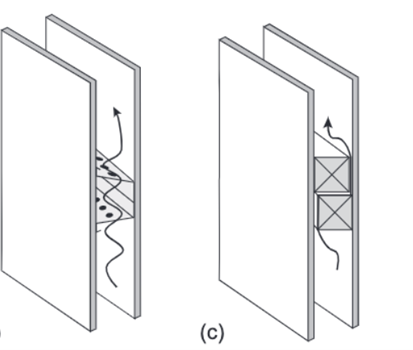

Fire propagation through and over ventilated facade systems is a key to achieving fire safety for occupants in and around the building and for emergency services. In the external layer of the building, cavities are the norm, especially in the UK where facades are generally ventilated to ensure adequate moisture control and weather tightness. These cavities can present significant path of fire spread in the event of a fire, resulting in loss of life and property.

Several literature reviews and large-scale experimental studies have been completed and research continues (see Reaction to fire performance – external surfaces). Various test methods are used throughout the world to assess and evaluate the performance of facade solutions, including cavity protection systems. According to the testing experience at BRE, flames in ventilation cavities can extend up to ten times further than flames outside the cavity, as reported by Colwell et al. An air cavity also contributes to increased burning rates in the cladding system, see Boström et al.

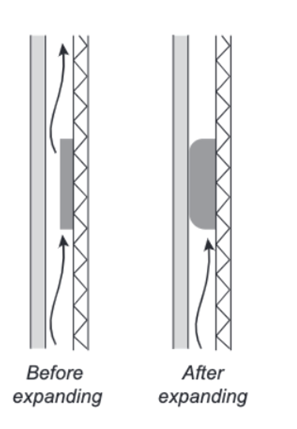

Careful detailing and third-party assured cavity and fire stopping products manage these risks, if installed and executed correctly. This needs specialist review and supply chain engagement, as the chosen cavity barrier must retain its ability to control moisture as well as perform adequately in the case of a fire. An overview from Fire Safe Use of Wood in Buildings. Global Design Guide illustrates the basic principles of managing fire spread, whilst allowing for ventilation, see below. The use of self-expanding, or intumescing, cavity barriers is often considered, and products are available for timber construction. This requires careful review and detailing, confirmation of acceptable activation temperatures and overall alignment with the fire safety objectives for the project. Early and continued liaison with the design, construction and client team is recommended to ensure compliant and reliable management of risks.

(Östman et al (2010), Östman and Mikkola, (2018), extract from Global Design Guide, 2022)

Other fire spread paths

Separating timber wall and floor assemblies covered the design of fire resisting timber construction, as has also been outlined earlier in this section. For this performance to be delivered it is assumed that:

- Joints between panels are tight or filled with fire resisting material,

- Linings are installed so joints are staggered and

- Fixings are inserted as per manufacturers’ instructions.

Joints between structural elements have also been covered, and standard set-up for wall-to-floor and floor-to-floor joints can be found for example in Table 9.1 Global guidelines for element joints in Fire Safe Use of Wood in Buildings. Global Design Guide.

Information on protecting the installation of building services and fire compartmentation, including service penetrations, exhaust systems and ventilation ducts, is available in Fire Safe Use of Wood in Buildings. Global Design Guide as well as here https://asfp.org.uk/page/Publicationslist.

Information on fire doors can be found here.

Bibliography (Technical level 2)

1 Boström, C. Skarin, M. Duny, R. McNamee, Fire test of ventilated and unventilated wooden facades, SP Report 2016:16, Borås, Sweden, 2016

2 Colwell, T. Baker, Fire Performance of external thermal insulation for walls of multistorey buildings, 3rd edition, IHS BRE Press, Garston, 2013

3 Östman, B and Buchanan, A, Fire Safe Use of Wood in Buildings. Global Design Guide

4 Östman, B et al, Fire Safety in Timber Buildings: Technical Guideline for Europe. SP Report 2010:19. Stockholm, Sweden

5 Östman, B, Mikkola, E (eds) (2018) Guidance on Fire Safety of Bio-Based Facades. Dissemination document N230-07 – COST Action FP 1404 | ETH Zurich

6 Structural Timber Association, Fire Safety In use guidance Volume 2 – Cavity barriers and fire stopping