To Search All Text On This Page

On Windows – Press Ctl+F

On Mac – Command+F

This site is suitable for a wide range of users, with technical information

levels 1 and 2 available on closed toggles

Technical level 1 Technical level 2

Basic requirements

- Statutory requirements

Sprinkler systems

- Residential sprinklers

- Water mist systems

- Fire safety design with sprinklers

Maintenance and resilience

- Periodic inspection

The main reasons for using active fire protection are to gain time for safe evacuation and to control or suppress a fire in order to minimise fire damage to contents and buildings.

Active fire protection will include a means of automatic fire detection as well as devices that control the growth, suppression or extinguishing of the fire. They may also include provisions to help the fire and rescue services to rescue occupants and minimise property damage and/or fight the fire.

According to the UK building code, sprinkler systems are required in buildings classified as purpose groups 3 to 7(a) where there is a top storey more than 30 m above ground level – offices, shops and commercial buildings, those used for assembly and recreation, industrial, storage and other non-residential use (except car parks for light vehicles) [1].

For residential buildings where a top storey is more than 11 m above ground level, a sprinkler system is required throughout the building. This is a recent amendment to the UK building code, which came into force in 2020, changing the trigger height from 30 to 11 m for the requirement of the provision of sprinklers in block of flats [2].

Statutory requirements (Technical level 1)

In buildings or parts of buildings where sprinkler systems are required, the design and installation of sprinkler systems for residential buildings must comply with the requirements of BS 9251, whereas non-residential sprinkler systems are required to comply with BS EN 12845[3]. In addition to these, however, sprinklers may be demanded by other (non-statutory) stakeholders such as insurance companies.

In order to match the capability of the sprinkler system to the type of risk it will have to face, risks are grouped into hazard classifications. There are three main divisions, each based on the expected fuel load of the occupancy and the rate of fire growth expected from the contents or processes:

- LH – light hazard (low combustible loading, with a slow rate of fire growth)

- OH – ordinary hazard (low to moderate combustible loading, with moderate to fast rate of fire growth)

- HH – high hazard (high combustible content, with fast to ultra-fast rate of fire growth).

The ordinary and high hazard classes are subdivided to further qualify the type of risk. The classifications principally depend upon the quantity and type of combustible materials contained in the risk, the speed at which a fire is likely to develop, and any processes that will produce particularly severe circumstances for fire propagation [4].

Fixed fire suppression systems control, suppress or extinguish a fire either by cooling and/or wetting unburnt material, by lowering the oxygen level or by chemical reaction. Typically, fixed fire suppression systems will be designed and installed to control or suppress fire growth, as opposed to completely extinguishing the fire, meaning that it is assumed that manual intervention is needed to complete the suppression.

This section mainly covers water-based sprinkler systems, as they are one of the most common types of active fire system.

Sprinkler systems were developed more than a century ago by the insurance industry for property and asset protection. Their applicability to the protection of life has only recently begun to be recognised, and relevant standards developed. Although in the past sprinkler systems have been installed to cover an entire building or complex, their suitability for localised high-risk areas is now recognized.

The installation of a sprinkler system may result in a reduction in insurance premiums, the amount of portable fire-fighting equipment necessary, and more flexibility in the design and use of the building.

Usually part of a package of fire precautions in a building, a sprinkler system consists of a reliable water supply that feeds an array of individual sprinkler heads mounted at the correct spacing on an appropriately sized network of hydraulic pipes. Water may be supplied from one or more tanks by gravity or pumps, or taken directly from the water main if sufficient pressure and flow are guaranteed at all times.

The heads do not operate in unison, as each is an individual heat detector. The typical operating temperature for a sprinkler head is 68oC, but the thermal inertia in the mass of the sprinkler head and associated thermal fuse, creates an inherent delay between the moment fire gases have reached this temperature in the proximity of the head and the head’s activation and water discharge. This delay is characterised by the Response Time Index (RTI).

There are several variations on the basic sprinkler design, intended to deal with unusual ambient conditions or particular risks. Many codes and standards are available to cover all aspects of the design, specification, installation and maintenance of sprinkler systems, e.g. EN 12845.

Sprinkler systems have a long and successful history. Correctly specified, installed and maintained, they have a high success rate in controlling or suppressing fires. The design and calculations take into account the size and construction of the building, the category of goods stored in it and the characterisation of occupancy. Water damage from sprinkler systems is minimal. Accidental discharge of water from sprinkler heads is an extremely rare event, as is water leaking from sprinkler pipe work.

Given that very few sprinkler heads may activate in the event of a fire, water damage from sprinkler systems is often minimal. The water supply from sprinklers is far less than from a fire brigade arriving at a much later stage. Accidental discharge of water from sprinkler heads is a rare event, as is water leaking from sprinkler pipe work.

Automatic sprinklers are the most commonly installed fire suppression systems and are often used to reduce risks that arise from the building’s use, e.g. in industry, to protect vulnerable individuals or high-value contents, or to compensate for the materials used in the building’s construction. They are also often used in modern buildings, such as airports or storage facilities, to allow extensive open spaces to be created without structural compartment walls. They may also be used to protect premises that are geographically isolated.

It is important that the reason for installation is understood and that, in those cases where the system has been provided as part of a fire engineering design for the building, the responsible person is made aware of and understands the interaction of the system and other building design and service features.

Residential sprinklers (Technical level 1)

Residential sprinklers, introduced in Northern America in the late 70’s as a new tool to reduce the high number of fire victims [5] are simpler systems, with the water supply directly connected to the ordinary tap water system. Experience shows they have been effective in saving lives, since they extinguish or delay a fire at an early stage and increase the time for escape [6]. Sprinklers in residential buildings should be designed in accordance with BS 9251.

Water mist systems (Technical level 1)

Water mist systems were originally developed to suppress fires in ship’s engine rooms. They discharge water as much finer droplets than conventional sprinkler systems, and typically have a relatively low water delivery rate. Unlike conventional sprinkler systems, water mist systems tend not to use interchangeable components, and therefore the design and installation of the complete system must be carefully controlled by a single supplier.

Water mist systems from different manufacturers may operate at different pressures, they may use pumps or pressurised cylinders to provide the driving force to discharge water through activated heads, and they may produce different droplet sizes. Therefore performance-based burning commodity tests are used to evaluate the main design parameters, such as nozzle type, nozzle spacing, nozzle installation height, minimum working pressure etc. In addition, individual components are subjected to component tests, which have been adopted from similar tests for conventional sprinkler system components.

Land-based water mist systems are proving particularly cost-effective in retro-fit applications, such as residential units, or to protect specific risks such as computer cabinets. They discharge water through specially developed nozzles to produce fine droplets – much smaller than traditional sprinkler systems.

Triggering is similar to that used with conventional sprinkler systems, typically using an individual glass bulb or fusible link to activate individual heads. The droplets are sufficiently small to be entrained by convective currents produced by the fire and can be drawn into and quickly cool the combustion zone or seat of the fire. They work best when used to control a growing fire in a relatively small compartment or room (as opposed to an assembly hall or warehouse), where the relatively fine water mist provides fire suppression by a combination of wetting, cooling and oxygen displacement.

Currently, the NFPA 750 [7] standard is available for design and installation, and further standardisation work is underway. As users of water mist fire suppression systems are dependent on the manufacturer’s information and data, the design and installation of a successful water mist system must be based on a risk assessment, taking into account the probable type and location of fire, the fuel and the immediate environment.

Fire safety design with sprinklers (Technical level 1)

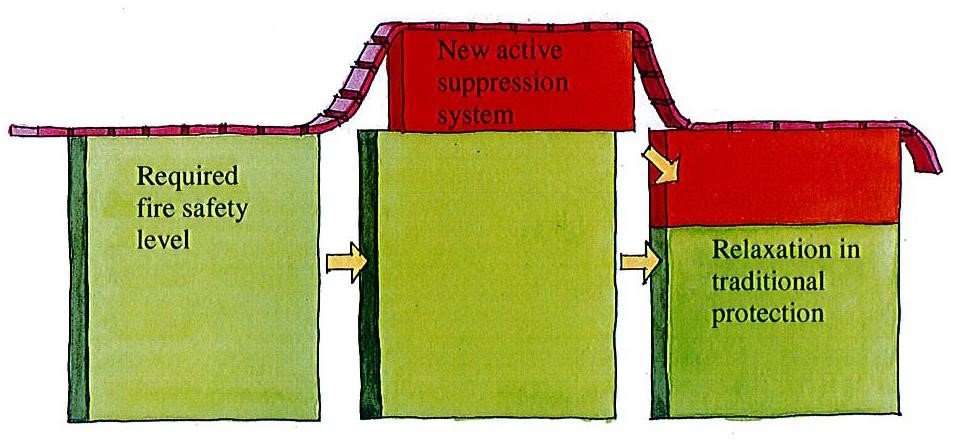

Figure 3: Principle for fire safety design by sprinklers. Increased fire safety by installation of sprinklers may lead to relaxations in the passive fire protection features, and still fulfil the same or higher safety level [8].

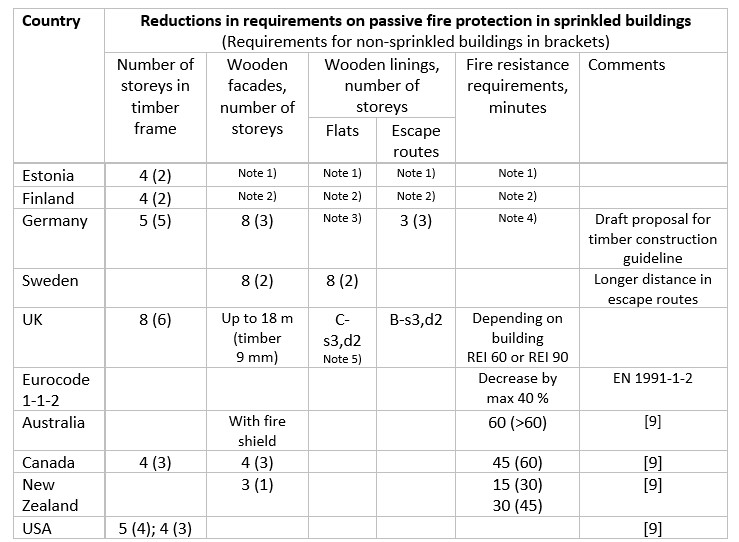

Sprinkler installation may provide special benefits for greater use of wood in buildings, although the implementation of alternative fire safety design with sprinklers may vary between countries. Some examples are given in Table 1. For more information see chapter 10 in Fire Safe Use of Wood in Buildings.

Table 1: Comparison of some reduced requirements for passive fire protection in sprinkled buildings in different countries.

Notes:

1) Estonia: Two of following requirements could be different when using sprinklers:

– Area of each storey of the building

– Area of fire compartment

– Length of escape route

– Fire resistance of load-bearing structures

– Fire resistance of separating structures between fire compartments

– Reaction to fire requirements of structures

– Fire spread limitation requirements to neighbouring buildings

2) Finland: Derogations may be allowed concerning:

– Gross floor area of the building and the areas of its fire compartments

– Length of passageways to exit

– Classification of fire load

– Constructions (slower rise in temperature and cooling of load-bearing constructions)

– Reaction-to-fire requirements of surfaces (internal & external)

– Distance between buildings

3) Germany: Combustible surfaces limited to 50 %

4) Germany: REI 60 for ≤ 400 m²

5) UK: Parts of wall can be of poorer performance than specified, provided the total area of those parts in any one room does not exceed one half of the floor area of the room, and subject to a maximum of 20 m² in domestic and 60 m² in non-residential premises.

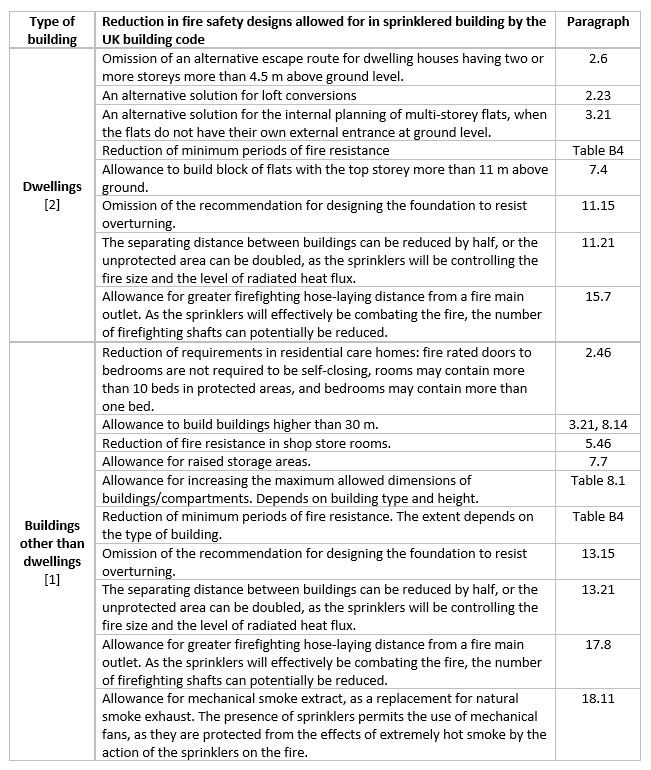

The UK building code is not as flexible when it comes to reduction of the passive protection in sprinklered buildings as, for example, the Swedish building code, where the difference between the allowance in non and sprinklered buildings is significantly greater for external and internal linings. There are however other alternative solutions which can be adopted using the UK building code in sprinklered buildings to achieve a reduction in the fire safety design. See Table 2.

Table 2: Alternative solutions allowed for in the UK building code in sprinklered buildings.

Notwithstanding the table above, further reduction in fire safety requirements with the provision of sprinklers could be possible by adopting a performance-based approach, where new alternative solutions could be derived or departures made from the building code. For information in regard to the performance-based fire safety design refer to Structural design approaches.

Maintenance and resilience

Fires in buildings are rare events, and both active and passive fire protection measures and systems must be serviced and maintained in order to ensure they will function when a fire occurs. Before a sprinkler system is taken into use however, it is also required to be tested prior to commission to ensure that the design objectives are met. In common with all piped services, the control of installation standards and proper commissioning and testing of the completed installations are very important. However, unlike other piped services, the completed installation will not normally be tested in full operational mode. Therefore, even greater care should be exercised to ensure that the design objectives are met.

The commissioning and testing normally carried out is likely to consist of the following elements[4]:

- Pneumatic and hydrostatic testing of installation pipework

- Water supply testing

- Alarms and monitoring facilities

- Third-party certification.

When the system is handed over to the user, a comprehensive operation and maintenance manual should be provided, which should contain:

- Full documentation for the entire system, its components and all associated plant, alarms, utility supplies, etc, including record drawings

- Instructions for the day-to-day operation of the system and procedures to be adopted in fire conditions

- A full schedule of all maintenance and testing required to keep the system in full working order.[4]

Periodic inspection (Technical level 1)

The sprinkler system must be inspected by a qualified person at least once a year. It is often wise for the user to have the testing, maintenance and servicing carried out under a service agreement with the installer or an accredited servicing company. The LPS 1048 scheme [10] lists contractors considered to be suitable for maintenance of sprinkler systems, and choosing a contractor from this list should bring an expectation of reliability and capability [4].

If a sprinkler system forms an integral part of the fire strategy for a building, it is necessary to ensure that management procedures are in place to cater for those periods when the sprinkler system is not functional. Such procedures may include the following:

- Limit any planned shutdown to lower-risk periods, when building occupant numbers are low (e.g. at night, at weekends or during public holidays)

- Isolate the area without working sprinklers from the rest of the premises by fire-resisting material

- Avoid high-risk processes such as ‘hot-work’

- Training and deployment of additional staff as fire patrols

- Suspension of phased evacuation. Evacuation of occupants should be immediate and total. (Exercise caution, as stairway widths may be designed for phased evacuation only)

- Inform the local fire and rescue service.

Bibliography (Technical level 2)

1 HM Government, Fire safety Approved document B, The building regulations, Volume 2: Building other than dwellings, 2020.

2 HM Government, Fire safety Approved document B, The building regulations, Volume 1: Dwellings, 2020.

3 EN 12845:2015 Fixed firefighting systems – Automatic sprinkler systems – Design, installation and maintenence.

4 Fire Safety Engineering, CBISE Guide E.

5 National Fire Protection Association, NFPA 13 R. Sprinkler systems for residential occupancies up to and including four stories in height.

6 J. Robertson, Building codes and NFPA Standards, Session 2 Water based fire suppression systems, Vancouver, Canada, 2000.

7 NFPA 750. Standard on Water Mist Fire Protection Systems, National Fire Protection Association, USA.

8 A. M. N. F. Östman B, Residential sprinklers save lifes – Experience and fire safety design with new possibilities (in Swedish), Trätek Publication 0202007, 2002.

9 Östman B, Alternative building design by residential sprinklers. Proceedings Interflam, 1269-1274, Edinburgh, 2001.

10 LPS 1048-1 Requirements for the approval of sprinkler systems contractors in the UK and Eire (Watford: BRE Certification).

11 Nystedt F, Verifying Alternatives in Building with Fire Sprinkler Systems, Department of Fire Safety Engineering and Systems Safety, Lund University, Sweden. Report 3150, 2010.