Cavity barriers and fire stops

To Search All Text On This Page

On Windows – Press Ctl+F

On Mac – Command+F

This site is suitable for a wide range of users, with technical information

levels 1 and 2 available on closed toggles

Technical level 1 Technical level 2

Cavity barriers and fire stops

- The difference between fire stops, cavity barriers and cavity closure

- How long should cavity barriers function?

- Hot or cold smoke

- Why they work

Cavity barrier and fire stop locations

- For single dwellings

- For multiple occupancy

- Example detail

Cavity barrier options

- External wall cavity

Cavity barriers and fire stops

Cavity barriers

A cavity barrier is a product within a concealed space or void that provides a barrier to slow the spread of fire.

The functional requirements of a cavity barrier are that, in the event of a fire that may occur or spread into a cavity space, the cavity barrier provides the following functions:

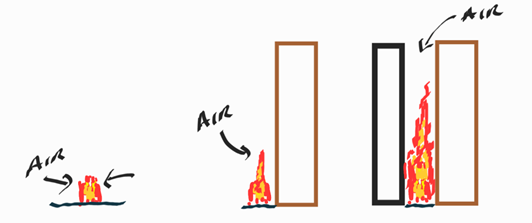

- To stop air being drawn through the cavity space, which would cause the fire to grow. If the fire does take hold in the cavity, then the cavity barrier will reduce the air ventilation to the fire.

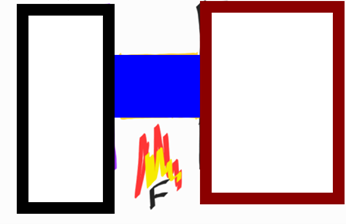

- Provide a time delay to limit the fire spread beyond the barrier location.

- To inhibit the passage of smoke for a reasonable time period.

Fire stops

A fire stop is a product used to provide continuity of a fire-resisting element where gaps, joints, openings or other imperfections would otherwise degrade the fire-resisting performance of that element.

The functional requirement of a fire stop is to close any gaps, joints, openings or other imperfections in fire-resisting elements to maintain the REI requirement of the element in the event of a fully-formed fire.

The difference between Fire Stops, Cavity Barriers and Cavity Closure terms

Cavity barriers are not fire stops. A fire stop is a barrier to stop fire for the duration of a fully developed fire or to be of the same fire resistance as the element of structure to which it is attached.

A cavity barrier is not fire-stopping unless it is designed for that function. However, fire-stopping can be achieved by a cavity barrier if it closes a cavity.

A cavity closure may not be the same as a cavity barrier, but a cavity barrier may act as a cavity closure. Common cavity closures are designed for masonry structures and may not be tested or suitable for structural timber buildings.

How long should cavity barriers function?

Building regulation provide guidance on the performance expectations of cavity barriers, covering both integrity (flame break-through) and insulation (heat above 180°C peak temperature) fire-resistance periods.

Hot or cold smoke

A fire generates smoke, which can be drawn through a cavity. A cavity barrier to stop smoke passing and manage gaps effectively.

Some open-state (sometimes referred to as open-vent) cavity barriers, such as intumescent cavity barriers, do not close all gaps until a certain temperature is reached. Open-state barriers for high-rise buildings with curtain walling are accepted world-wide. The use of intumescent barriers is a practicable and demonstratable solution for external wall cavities where tolerances of fit can be taken up with the expanding intumescent.

Fire engineers will commonly accept open-state intumescent cavity barriers based on test evidence from BRE testing carried out by NHBC/BRE in 2013 (NF51 fire in cavities in residential buildings) [1].

Open-state barriers, however, do not stop air draw in the initial stages of a fire; they stop ventilation once they have closed, arresting the replenishment of air only from that point.

Why they work

To understand cavity barriers, it is necessary to appreciate the behaviour of fire within an enclosed space, such as a cavity between a timber external wall and the cladding material.

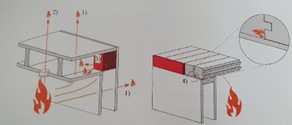

Figure 1: Fire behavour influenced by ventlation with the height of flames in a cavity space extending by up to a factor of 10

Cavity barrier reduces the draw of air and ventilaton in a cavity space

Figure 2: Cavity barriers provide a resistance (integrity and insulation) for a period of time.

Different types of fire stopping

Typical timber construction methods will introduce junctions and gaps between the construction elements and require penetrations for services. Construction gaps and joints in fire-resisting elements could present a route for flames and hot gases to spread into neighbouring compartments and therefore must be sealed using fire-stopping materials to prevent the spread of fire.

The fire-stopping of fire-resisting elements can be required for many reasons (see Figure 3):

- Service penetrations

- At the junctions between fire-resisting elements

- To prevent exposing the timber structure to high temperatures prior to the failure of the fire protection system.

- To provide continuity of compartmentation into cavity spaces

Figure 3: Routes for fire to bypass fire-resisting elements

Fire-stopping can be tested as part of a full-scale fire test, in a wall to BS EN 1365-1, or in floors to BS EN 1365-2, or as small-scale fire tests for different applications to the following standards:

- BS EN 1366-3 – Penetration Seals

- BS EN 1366-4 – Linear Joint Seals

Any fire-stopping test must be relevant for the construction method being used, and variations between the as-built construction and the tested assembly may invalidate the application of the test results. Alternatively, it may be possible to demonstrate the effect of small gaps and joints using the methods provided in BS EN 1995-1-2 or other guidance documents.

It is best to design-out the need for pipes and services that penetrate fire-resisting elements using dedicated service risers, but they cannot be designed out completely. Different fire-stopping strategies exist for different service penetrations depending on the size and type of service. For example, a pipe penetration can be fire stopped using the following different methods:

- A pipe or cable with a diameter less than a specified minimum (normally 40mm).

- A fire resisting enclosure.

- A casing that provides the appropriate fire resistance from the outside.

- Intumescent collars that compress the pipe and close off the opening.

- A fire resisting sleeve that extends a specified distance beyond the fire resisting elements if the pipe made from a high melting point metal.

- Proprietary tested pipe seals.

- An automatically activated fire shutter.

Where service penetrations have been tested as part of a fire-resisting element, additional fire stopping may not be required.

Cavity barrier and fire stop locations (Technical level 1)

Statutory Building Regulation guidance presents the requirements for the locations of cavity barriers. Requirements can vary across the UK. In addition to guidance in the Building regulations, other publications are available: for example for lower rise construction, The Structural Timber Association Fire Safety In use guidance Volume 2 – Cavity barriers and fire stopping [3].

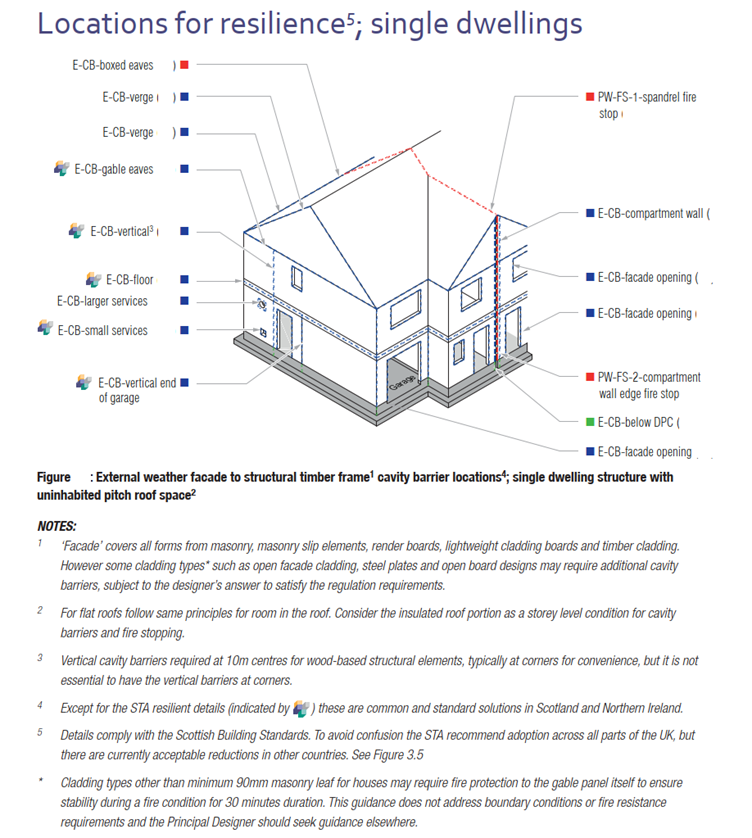

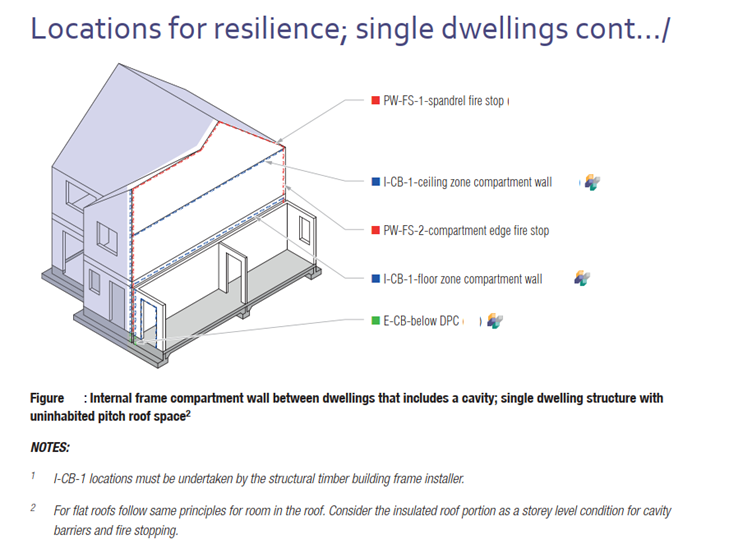

For single dwellings

(Taken from STA’s Fire Safety In use guidance Volume 2 – Cavity barriers and fire stopping)

(Taken from STA’s Fire Safety In use guidance Volume 2 – Cavity barriers and fire stopping)

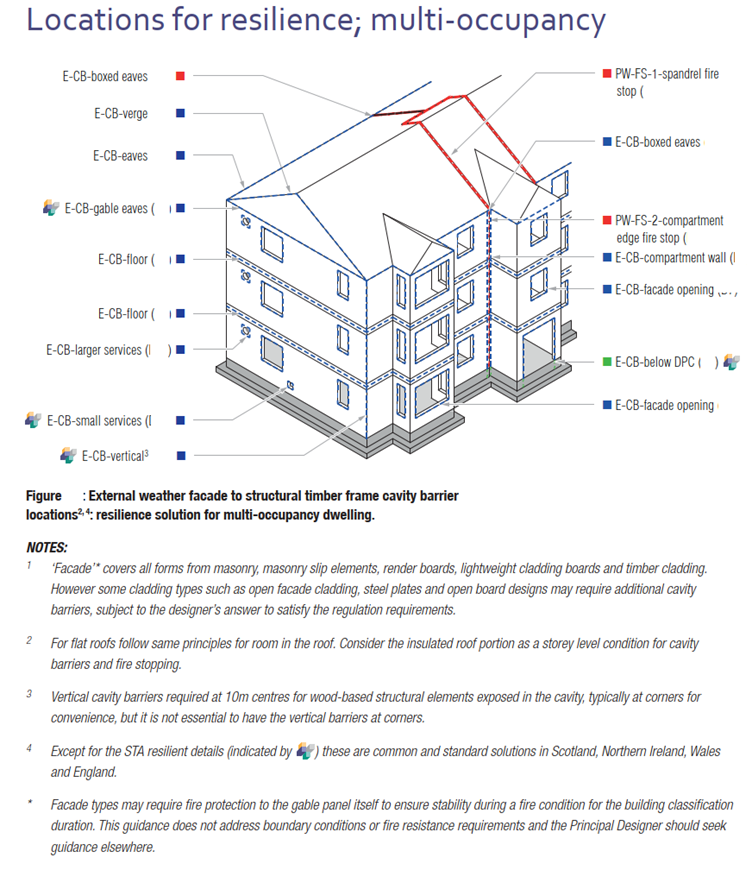

For multiple occupancy

(Taken from STA’s Fire Safety In use guidance Volume 2 – Cavity barriers and fire stopping)

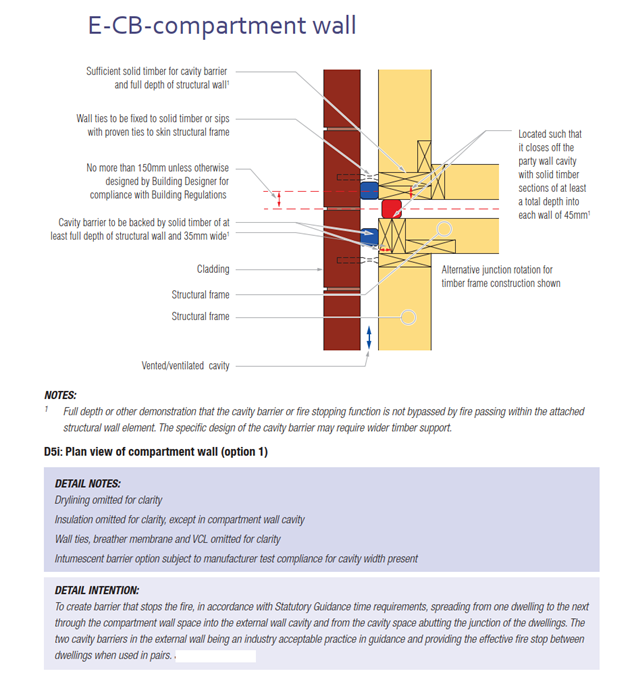

Example detail

(Taken from STA’s Fire Safety In use guidance Volume 2 – Cavity barriers and fire stopping)

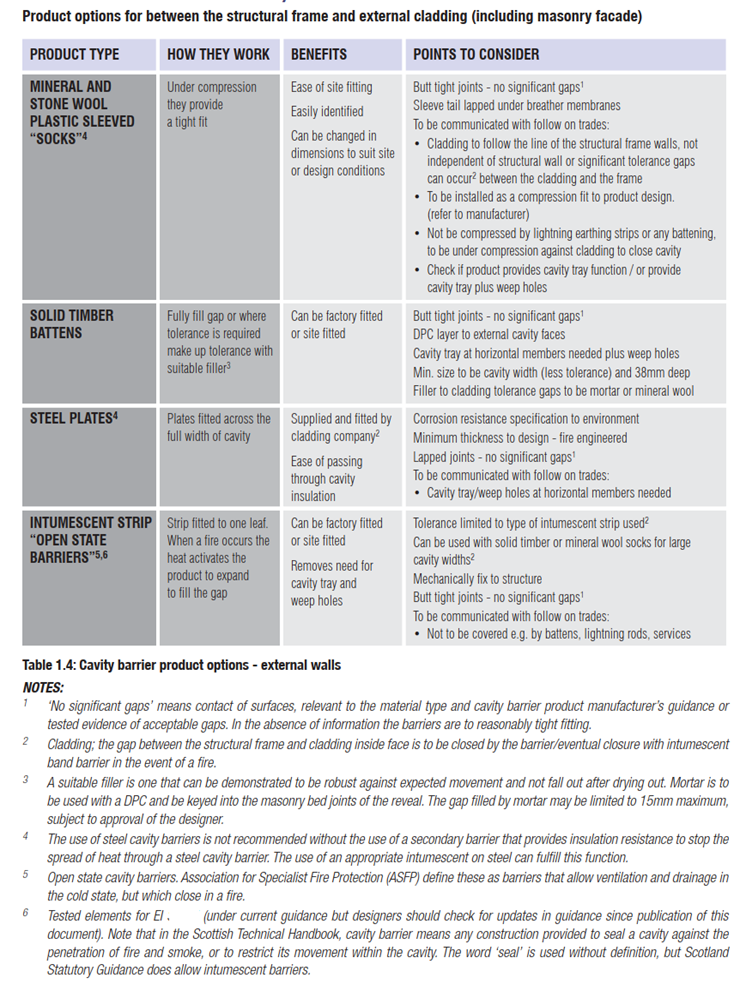

There are three common types of cavity barriers used in the UK:

- Mineral wool (which must now be stone wool) socks,

- Solid timber battens

- Intumescent strips (sometimes called open-state cavity barriers).

(Taken from STA’s Fire Safety In use guidance Volume 2 – Cavity barriers and fire stopping)

Approval of applications (Technical level 1)

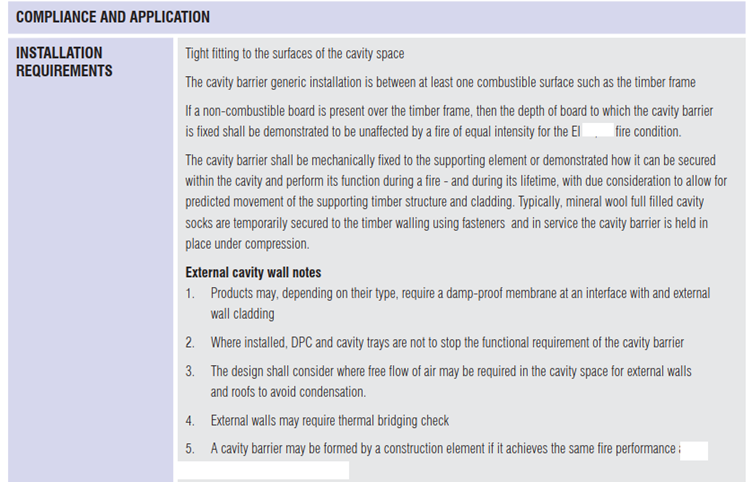

Statutory guidance requires cavity barriers to be tested except for around openings deemed to satisfy solutions as listed by each regulation authority in their relevant guidance documents. Tests are to be to the similar or worse case condition of the cavity components and conditions being used – for example, a test for masonry to timber frame will not be suitable for timber cladding to timber fame.

Fire barrier installation (Technical level 1)

Cavity barriers should be tightly fitted to a rigid construction and mechanically fixed in position to one face of the cavity. Common practice for cavity external walls is for mineral wool socks to be stapled in position on one side only, but as they need to be under compression to work, the fixing is not relevant in service; the fixing being a temporary need until the outer leaf is assembled. Timber battens are fixed with fasteners.

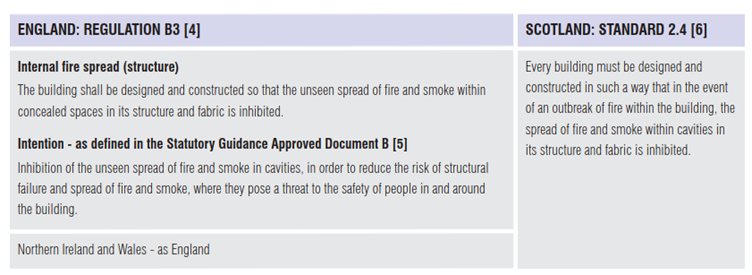

Cavity barrier regulation requirement (Technical level 1)

(Taken from STA’s Fire Safety In use guidance Volume 2 – Cavity barriers and fire stopping)

(Taken from STA’s Fire Safety In use guidance Volume 2 – Cavity barriers and fire stopping)

Analysis of fire spread in timber structures (Technical level 1)

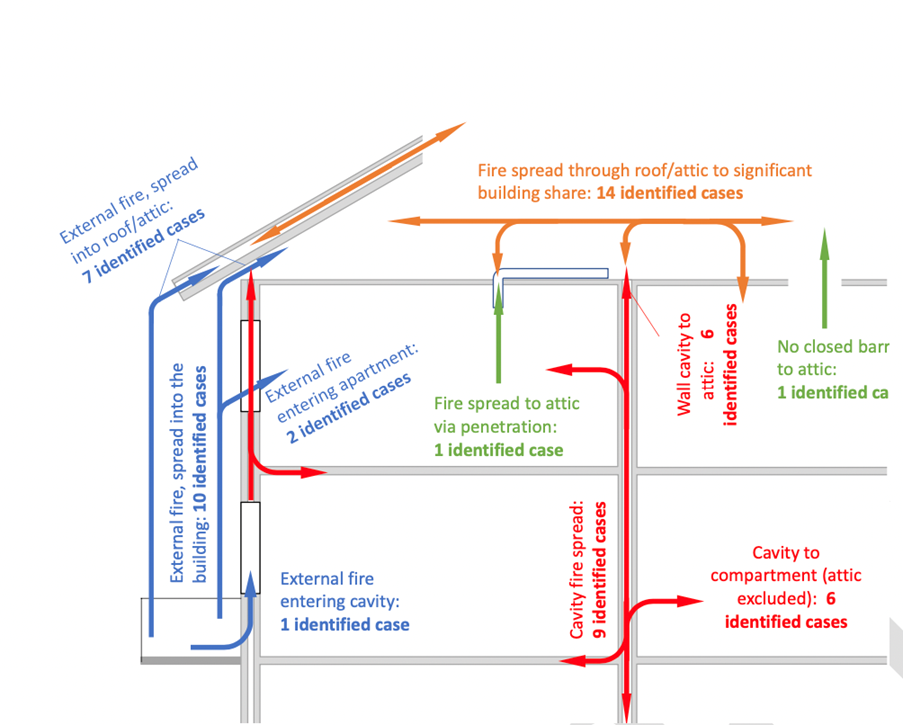

To allow improvement of property protection of timber buildings (structure), a number of high damage fires were analysed. The main paths of fire spread were identified, using accident reports, news articles or any other information. This qualitative study indicates that the most significant modes of fire spread have been:

- Fire spread through the attic to large parts of the building.

- Fire spread along the facade entering the building (most commonly into the attic).

- Fire spread through wall and floor cavities.

In this study, attic fire spread was the most common path of significant fire spread, leading to fire in significant parts of the building. It should, however, be noted that a fire rarely starts in the attic (only in one of the 33 analysed fires started in the attic). Of the analysed fires, the most common ways the fire entered the attic are:

- external fires (commonly starting on a balcony) traveling through the eave

- cavity fires traveling to the attic

Figure 4: Identified paths of fire spread in fires that involved at least three fire compartments.

The full study, including methods, qualification and limitations please read in full here.

References

- HIS BRE Press. PUB NF 51 Fires in cavities in residential buildings – the performance of cavity barriers in external walls with combustible materials, 2013

- Paper on Pyrolysis

- Structural Timber Association. Fire Safety In use guidance Volume 2 – Cavity barriers and fire stopping, 2021

- BS EN 1365-1

- BS EN 1365-2

- BS EN 1366-3

- BS EN 1366-4

- BS EN 1995-1-2

- SP Report 2010:19 Fire Safety in Timber Buildings